Customization of silo liner

Self-lubricating/Anti-impact /Wear-resistant /No residue in the silo

Product information

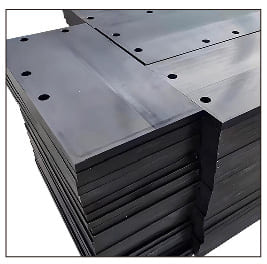

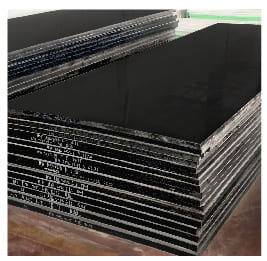

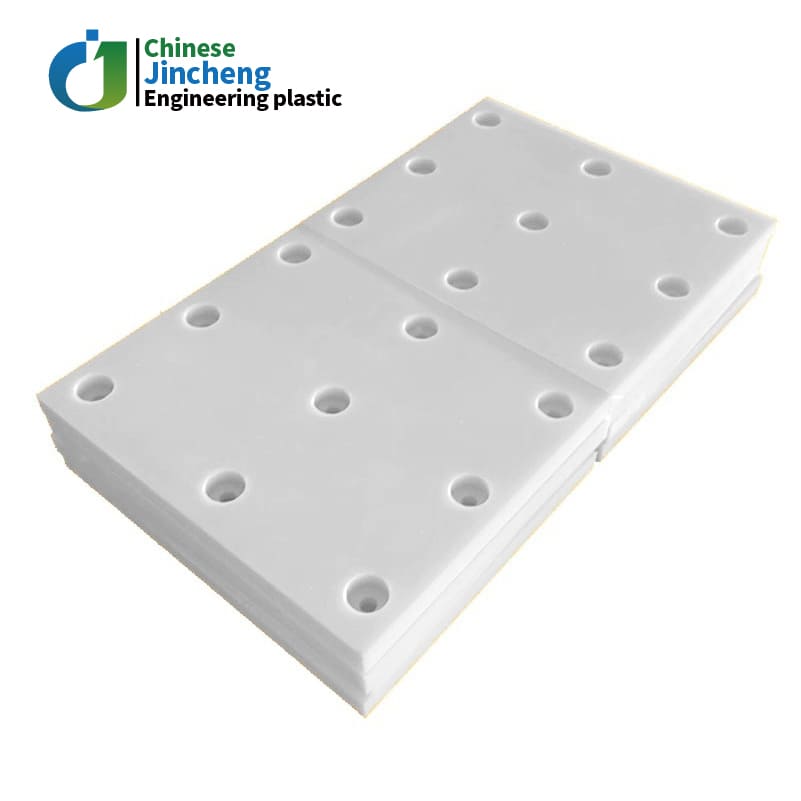

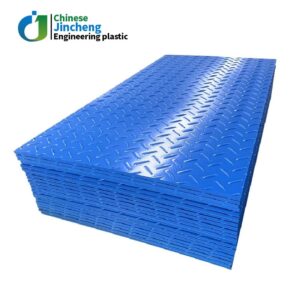

Name: Silo Liner/Slide Plate

Material: Ultra-high Molecular Weight Polyethylene

Specification:Customized non-standard

Feature: Self-lubricating,non-water-absorbing, anti-impact

Range: Silos, coal bunkers, carriages, hoppers, etc.

Manufacturer: Hebei Jincheng Rubber & Plastic Co., Ltd.

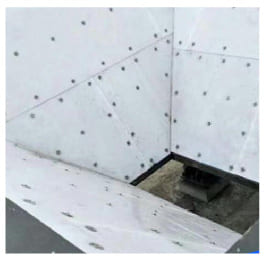

The silo liner is a type of plate used to protect the inner wall of the coal bunker.

Main functions

Reduce the friction coefficient

During the process of loading and unloading coal in the coal bunker, there will be a large

friction force between the coal and the bunker wall. The silo liner has an extremely low

friction coefficient, which can effectively reduce the resistance during the flow of coal, enabling

the coal to flow smoothly in the coal bunker and avoiding the phenomenon of bunker blockage.

Protect the bunker wall

During the loading, unloading and storage of coal, it will cause wear and impact on the bunker

wall. The silo liner has high wear resistance and impact resistance, which can protect the bunker

wall from damage and extend the service life of the coal bunker.

Prevent corrosion

Coal may contain some corrosive substances, such as sulfur. The silo liner has good corrosion resistance,

which can prevent the bunker wall from being corroded and ensure the safe operation of the coal bunker.

Material

Ultra-high Molecular Weight Polyethylene (UHMWPE) The silo liner of this material has extremely

high wear resistance,impact resistance and self-lubricating property, low friction coefficient and strong

corrosion resistance. It is one of the most widely used materials for coal bunker liners at present.

Installation methods

Bolt fixation

Drill holes on the coal bunker wall, and then fix the silo liner on the bunker wall with bolts.

This installation method is firm and reliable,but it requires drilling holes on the bunker wall,

which may cause certain damage to the bunker wall.

Welding fixation

For some special materials of silo liners, the welding method can be used to fix them on the bunker

wall. The welding fixation method is firmly installed, but it requires professional welding equipment

and technicians, and the installation cost is relatively high.

Product advantages

| 01 Cut flat |

| 02Self-lubricating property |

| 03Customized on demand |

| 04Corrosion resistance |

Reviews

There are no reviews yet.