In the large family of engineering plastics, there is a material that stands out with its “versatile capabilities”: it can not only maintain toughness in extremely cold environments but also resist wear under high-frequency friction; it can not only support the precise operation of artificial joints but also ensure the long-term durability of industrial equipment — this is Ultra-High Molecular Weight Polyethylene (UHMWPE).

Core Definition: What is “Ultra-High Molecular Weight”?

“Ultra-High Molecular Weight” is the fundamental source of all its outstanding properties.

- Regular polyethylene: Its molecular weight ranges from tens of thousands to hundreds of thousands.

- Ultra-High Molecular Weight Polyethylene (UHMWPE): Its molecular weight is usually more than 1.5 million, and can even reach 8 million to 10 million. This means its molecular chains are extremely long.

Here comes the key point.

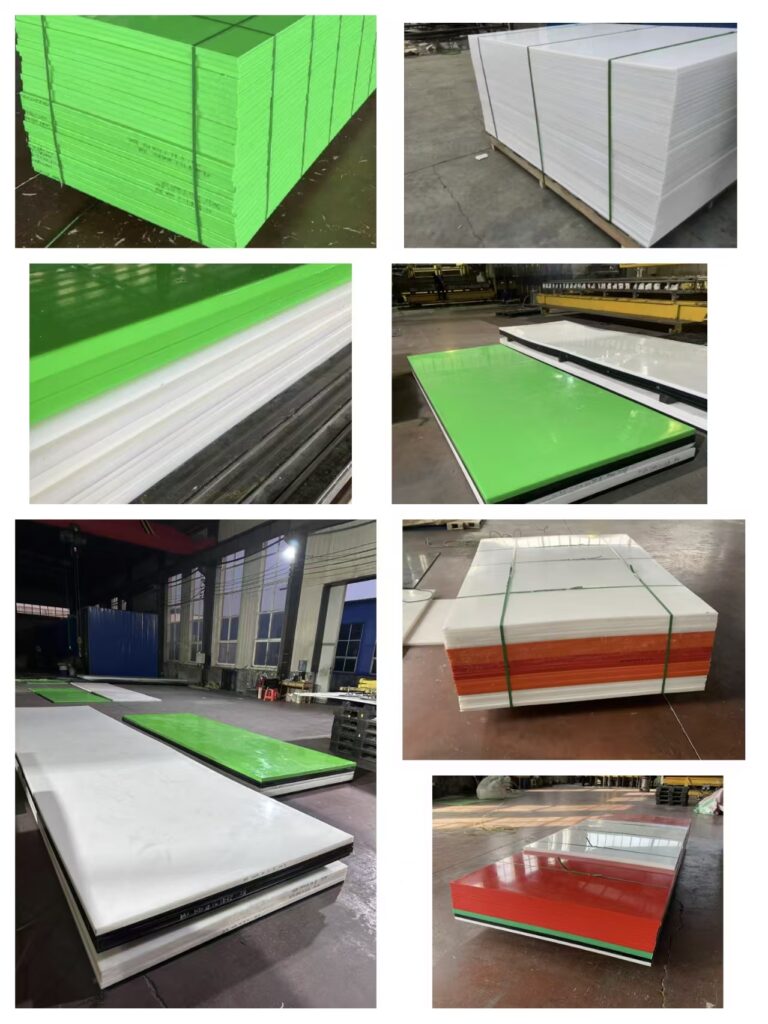

Hebei Jincheng Rubber & Plastic Products Co., Ltd. specializes in the production of ultra-high molecular weight polyethylene (UHMWPE) sheets. Equipped with large gantry milling machines, CNC lathes and precision machining centers, the company can manufacture various precision machined parts.

- Ultra-High Molecular Weight Polyethylene (UHMWPE) Sheets: Processed with Virgin Materials

- Color: 8 options available for you, including yellow, green, blue, purple, white, black, orange and red.

- Molecular Weight: 3.5 million, 5 million, 7.5 million and 9 million, which can meet the requirements of different working environments.

- Dimensions:

- Thickness: The general thickness of the sheets ranges from 10mm to 70mm. Among them, the thickness of black and white sheets can be customized up to 115mm. The thickness usually has a positive tolerance of 1-2mm; precise thickness can be achieved through processing if needed.

- Length: 4100mm, 6140mm

- Width: 1550mm, 1630mm

2.Polyethylene Chain Guide Wear Strip

- Color: Green, white, black, etc.

- Model: T-type single row, T-type double row, CT-type, TS-type, K-type, CKG-type, CKG-V type, CKG-H type, etc.

3.Chain Plate Turning Guide Rail

- Color: Green, white, black, purple, etc.

- Model: Single-row, multi-row, magnetic, non-magnetic, etc.

4.Chain Guide Rail for Knife-Edge Turning Machine

- Color: Green, white, black, etc.

- Applicable Industries: Knife-edge turning machines, food industry, logistics industry, pharmaceutical industry

5.Star Wheel Dial/Guard Plate for Filling Machine

- Material: Customizable and processable polyethylene, nylon, polytetrafluoroethylene (PTFE), polyoxymethylene (POM)

- With numerous product parameters, customization is available based on drawings or samples (by sending samples)

6.Bottle Dividing Screw

- Material: Customizable polyethylene, nylon, polyoxymethylene (POM), polytetrafluoroethylene (PTFE)

- Color: Green, white, yellow, etc.

7.Aluminum Can Turner: White

- Model:

- 500ML (Can diameter: 66mm, Height: 169mm)

- Short can 330ML (Can diameter: 66mm, Height: 115mm)

- Tall can 330ML (Can diameter: 58mm, Height: 147mm)

- Short can 240ML (Can diameter: 66mm, Height: 92mm)

- Tall can 240ML (Can diameter: 53mm, Height: 133mm)

- Customization is available according to your can/bottle shape. It ensures no jamming or tipping at high speed and supports 90°, 180°, and 360° flipping.

The Foundation of “Omnipotence”: Seven Core Properties That Break the Boundaries of Material Performance

UHMWPE’s “omnipotence” is not unfounded; it is built on seven core performance advantages derived from its unique molecular structure—a linear architecture with a relative molecular weight exceeding 1.5 million. Each advantage precisely addresses key needs in both industrial and consumer applications.

1.Abrasion Resistance: The Reputation of “Abrasion King” is Well-Deserved

- In material wear tests, the abrasion resistance of UHMWPE is a benchmark in the industry—it is 7-10 times that of carbon steel, 4 times that of nylon, and 2 times that of polytetrafluoroethylene (PTFE). Whether it is used as liners for mining machinery, scrapers for grain conveying, or pulleys for textile machines, it can reduce wear with an extremely low friction coefficient (0.1-0.2) in scenarios involving “high-frequency friction + material impact”. For example, the service life of a chute liner made of UHMWPE in a coal mine is 5 times longer than that of a traditional steel plate, saving the enterprise nearly one million yuan in replacement costs annually.

- Analogy: If UHMWPE and nylon are rubbed on the same sandpaper, the wear loss of UHMWPE is much smaller than that of nylon.

2.Impact Resistance: Remains “Highly Tough” Even at -196°C

Unlike ordinary plastics that tend to become brittle and crack at low temperatures, UHMWPE has a brittle temperature as low as -169°C. Even in a liquid nitrogen environment, it still maintains excellent impact resistance—its impact strength is 5 times that of ABS plastic and 2 times that of polycarbonate.

- This property makes it a “life-saving material” for equipment in extremely cold areas: the inner lining of oil pipelines at Arctic research stations, handling pallets in low-temperature cold storage, and even the outer shell components of deep-sea exploration equipment all rely on it to resist impact and extrusion in extreme environments, preventing safety accidents caused by material cracking.

3.Self-Lubrication: A “Low-Maintenance Material” That Requires No Lubricating Oil

- During mechanical operation, the leakage and replacement of lubricating oil not only increase costs but also risk environmental pollution (e.g., in the food and medical fields). However, UHMWPE has an inherent “self-lubricating property,” with a surface smoothness comparable to that of metal surfaces coated with lubricating oil, allowing it to directly replace components that require lubrication.

- For instance, after food processing plants adopt UHMWPE for conveyor rollers, there is no need for regular lubricating oil addition. This not only eliminates the risk of food contamination by oil stains but also reduces equipment maintenance frequency, cutting annual maintenance costs by more than 30%.

4.Chemical Resistance: Withstands the Test of Over 80 Organic Solvents

- In corrosive environments such as chemical engineering and environmental protection, the chemical resistance of materials directly determines the service life of equipment. Except for strong oxidizing acids (e.g., concentrated nitric acid, concentrated sulfuric acid), UHMWPE can withstand long-term immersion in more than 80 organic solvents (e.g., ethanol, acetone, toluene) without dissolution, deformation, or aging.

- A pharmaceutical company uses UHMWPE to make reactor liners. When in long-term contact with acid-base solutions, these liners have a service life of over 5 years, far exceeding the 2-year cycle of traditional stainless steel liners. Its stability is second only to that of polytetrafluoroethylene (PTFE).

5.Anti-Adhesion: An “Anti-Sticking Tool” for Material Handling

- UHMWPE also possesses excellent anti-adhesion properties, derived from its extremely low surface energy and smooth molecular structure—making it difficult for various viscous or wet materials to adhere to its surface. In material handling scenarios, this property effectively solves the industry pain point of “material sticking to walls and caking.”

- For example, in the grain processing industry, grains like corn and wheat tend to stick to the inner walls of conveying equipment in humid environments. However, grain conveying pipelines and silo liners made of UHMWPE allow grains to slide smoothly without residue, reducing equipment downtime caused by cleaning wall-stuck materials and improving processing efficiency.

- In the food processing field, after using UHMWPE for the inner lining of molds for candies and chocolates, finished products can be easily demolded without additional release agents—ensuring food hygiene while simplifying the production process.

- In the chemical industry, if the inner walls of mixing tanks for handling viscous materials (such as resins and coatings) are lined with UHMWPE, uneven mixing caused by material adhesion can be avoided. At the same time, it reduces equipment cleaning difficulty, decreases the usage of chemical cleaning agents, and lowers environmental protection costs.

6.Lightweight: A “Weight-Reducing Expert” That Is 8 Times Lighter Than Steel

- In the aerospace, automotive, and drone industries that pursue “lightweighting,” the low density of UHMWPE (0.93-0.94g/cm³) is a core advantage—its density is only 1/8 that of steel and 1/2 that of aluminum alloy.

- For example, after a drone company replaced the aluminum alloy fuselage structural parts with UHMWPE composite materials, the fuselage weight was reduced by 40%, and the battery life was extended by 25%. In the new energy vehicle field, battery trays made of UHMWPE are 30% lighter than traditional steel trays, which indirectly increases the vehicle’s driving range.

7.Biocompatibility: Non-Toxic, Tasteless, and Odorless

It can be used in the food and medical industries, with excellent compatibility with human tissues.

Main Application Fields

Leveraging the aforementioned unique properties, UHMWPE has excelled in numerous fields:

1. Industrial Field

- Lining Materials: Liners for coal bunkers, silos, and chutes, which prevent material blockage and wear.

- Textile Machinery: Gears, cams, bearing housings, shuttle guides, etc., featuring low noise, wear resistance, and self-lubrication.

- Packaging Machinery: Chain guides, star wheels, conveyor accessories, etc.

2. Other Fields

- Food Industry: Cutting boards, conveyor chains, rollers, etc., which meet hygiene standards.

- Automotive Industry: Buffer pads, cargo box linings, etc.

Comparison with Other Common Engineering Plastics

| Property | UHMWPE | Nylon (PA) | Polyoxymethylene (POM) | PTFE (Teflon) |

| Abrasion Resistance | Excellent | Very Good | Good | Good |

| Coefficient of Friction | Very Low | Low | Low | Lowest |

| Impact Resistance | Excellent | Good | Poor | Fair |

| Temperature Resistance | Poor (≤80-100°C) | Good (≤120°C) | Good (≤100°C) | Excellent (≤260°C) |

| Chemical Resistance | Very Good | Fair | Fair | Optimal |

| Processability | Difficult | Easy | Easy | Difficult |