In the material conveying systems of industries such as mining, chemical engineering, grain, and building materials, conveyor scrapers are core vulnerable components. Traditional scrapers (e.g., steel scrapers, ordinary plastic scrapers) suffer from fast wear, easy material jamming, and frequent maintenance, which often cause production line shutdowns and increase enterprise operating costs. However, UHMWPE wear-resistant scrapers, with their excellent wear resistance, impact resistance, and self-lubricating properties, have become a new-generation preferred alternative to traditional scrapers, effectively extending equipment service life and reducing maintenance costs.

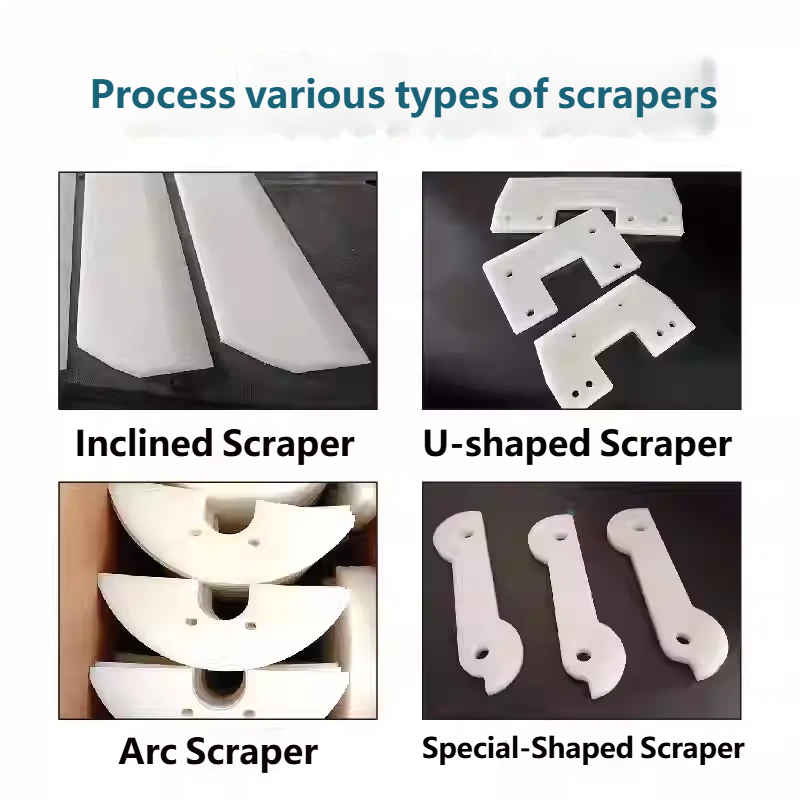

1. Product Matrix and Structural Characteristics

1.1 Inclined Scrapers

- Structural Design: Adopts a flat-plate structure with inclined cutting edges. The angle of the cutting edge (conventional 15°-30°, customizable on demand) is precisely machined to ensure tight fit with the conveying plane.

- Core Application: Suitable for material scraping operations of flat conveying equipment (e.g., belt conveyors, vibrating screens). It can efficiently clean residual materials on flat surfaces, avoid accumulation and blockage, and improve the conveying efficiency of equipment.

1.2 U-Shaped Scrapers

- Structural Design: Features a U-shaped contour with standardized mounting holes, boasting a compact structure and strong adaptability.

- Core Application: Mostly used in material cleaning scenarios around pipelines and U-shaped troughs. It can also serve as an auxiliary fixing component for pipe bodies, realizing the dual functions of “material scraping + fixing”. It is commonly found in auxiliary systems of fluid conveying equipment (e.g., U-shaped trough cleaning of soda ash conveying pipelines, auxiliary fixing of chemical solvent conveying pipes).

1.3 Arc Scrapers

- Structural Design: The arc-shaped surface can be customized according to the inner diameter of circular equipment, perfectly matching the curvature of the inner wall to achieve full arc surface fit.

- Core Application: Adapts to the arc surface scraping needs of inner walls of mixers, arc-shaped silos, rotary drying equipment, etc. It can completely remove materials adhering to the arc surface (e.g., residual mortar on the inner wall of cement mixers, material sticking to the inner wall of iron ore rotary kilns), reducing material waste and equipment scaling.

1.4 Special-Shaped Scrapers

- Structural Design: No fixed shape restrictions; fully customized according to the special working positions of non-standard equipment (e.g., arc-shaped sorting troughs of specialized separators, variable-diameter conveying sections of non-standard conveyors).

- Core Application: Serves the exclusive scraping positions of various customized industrial equipment (e.g., specialized separators, non-standard conveyors), solving the pain points of non-standard scenarios where traditional standard scrapers cannot be adapted.

2. Core Advantages of UHMWPE Scrapers: Addressing Key Conveyance Pain Points

Compared with traditional scraper materials such as steel, ordinary polyethylene (PE), and nylon, the advantages of UHMWPE scrapers focus on the three core needs of “reducing wear, lowering energy consumption, and minimizing maintenance”, which are fully suitable for industrial-grade continuous conveying scenarios.

| Performance Indicator | Value Range | Comparative Advantage (vs. Steel Scrapers) |

|---|---|---|

| Density | 0.93-0.94 g/cm³ | Weighs only 1/8 of steel, making installation easier |

| Volume Wear Rate | ≤0.0005 cm³/(N·m) | 6-8 times more wear-resistant than steel, with longer service life |

| Notched Impact Strength | ≥100 kJ/m² | 2 times more impact-resistant than steel, not easy to break |

| Dynamic Friction Coefficient | 0.05-0.1 | Low friction resistance, reducing motor energy consumption |

| Operating Temperature Range | -200℃ ~ 80℃ | Resistant to low temperatures without embrittlement and high temperatures without deformation |

| Corrosion Resistance | Resistant to strong acids, strong alkalis, and salts | No rusting, adaptable to corrosive chemical environments |

3. Comparison with Traditional Scrapers: Why Choose UHMWPE?

Many enterprises still use steel or ordinary plastic scrapers but ignore “hidden costs” (e.g., shutdown losses, frequent replacement costs). The following comparison clearly shows the “long-term cost-effectiveness advantage” of UHMWPE scrapers.

| Comparison Dimension | Ultra-High Molecular Weight Polyethylene (UHMWPE) Scrapers | Steel Scrapers | Ordinary Polyethylene (PE) Scrapers |

|---|---|---|---|

| Wear Resistance | ★★★★★ | ★★☆☆☆ (Prone to wear and rust) | ★★★☆☆ (Faster wear than UHMWPE) |

| Impact Resistance | ★★★★★ | ★★★☆☆ (Prone to breakage) | ★★☆☆☆ (Prone to embrittlement at low temperatures) |

| Installation & Maintenance Cost | ★★★★★ (Lightweight, installable by one person) | ★☆☆☆☆ (Requires hoisting, more labor needed) | ★★★★☆ (Lightweight but short service life) |

| Long-Term Usage Cost | ★★★★★ (Long service life, less replacement) | ★☆☆☆☆ (Frequent replacement + shutdown losses) | ★★☆☆☆ (High replacement frequency) |

| Adaptability to Harsh Working Conditions | ★★★★★ (Corrosion-resistant, low-temperature resistant) | ★★☆☆☆ (Prone to rust, not low-temperature resistant) | ★★☆☆☆ (Not impact-resistant, not corrosion-resistant) |

4. Industry Application Overview

- Chemical Industry: Used for conveying corrosive materials such as chemical fertilizers, soda ash, and salts (e.g., residual scraping of chemical fertilizer granular belt conveyors, inner wall cleaning of salt slurry conveying pipelines). It is resistant to acid and alkali corrosion, does not react chemically with materials, and ensures material purity.

- Grain/Food Industry: Used for conveying easily sticky materials such as grains, flour, and feed (e.g., residual cleaning of flour scraper conveyors, inner wall scraping of feed mixing equipment). Its food-grade material is non-sticky and easy to clean, ensuring no material contamination.

- Building Materials Industry: Cleans residual materials in cement mixers, sand-stone mixers, and screw conveyors (e.g., inner wall sticky sand cleaning of sand-stone screw conveyors, residual mortar scraping of cement mixers). It improves raw material utilization and extends the equipment cleaning cycle.

- Mining/Coal Industry: Used for conveying hard materials such as coal, ores, and slag (e.g., coal slag scraping of underground coal mine scraper conveyors, residual cleaning of ore conveying belts). It resists high impact and high wear, and prevents conveyor belt scratches caused by scraper breakage.

- Pharmaceutical Industry: Serves high-precision scraping processes of pharmaceutical powders (e.g., powder scraping of fluidized bed dryers, precise feeding of pharmaceutical-specific scraper conveyors). Its special-shaped design can accurately adapt to the special working positions of pharmaceutical equipment, meeting clean production requirements.

5. Customized Processing and Value Proposition

- Precise Customization: Relying on CNC machining technology, 3D modeling can be carried out based on equipment CAD drawings and physical samples, ensuring 100% adaptation between the scraper and the equipment and eliminating dead corners of material residue (e.g., customization of arc scrapers for non-standard rotary dryers, processing of special-shaped scraping components for specialized separators).

- Efficiency Improvement: Optimize the scraping angle and shape to reduce material accumulation (e.g., adjust the inclination angle of the scraper edge for sticky materials, optimize the curvature of the scraper surface for arc-shaped equipment), improve equipment conveying and mixing efficiency, and indirectly reduce energy loss.

- Cost Optimization: The wear-resistant material extends equipment service life, and the customized design reduces the frequency of spare part replacement. The comprehensive operation and maintenance costs are reduced by more than 30% compared with traditional steel scrapers.

In conclusion, through “performance advantages + scenario adaptation + customized services”, UHMWPE wear-resistant scrapers can accurately address the industry pain points of traditional scrapers such as “fast wear, frequent maintenance, and high costs”, providing a long-term and stable low-cost solution for material conveying systems in industries such as mining, chemical engineering, and grain.