In material conveyance systems, the performance of equipment at curve sections often determines the efficiency and stability of the entire production line. The problems of traditional metal blade curve conveyors—such as easy wear, material jamming, and high maintenance costs—have long been a “persistent headache” for enterprises in production. However, the emergence of ultra-high molecular weight polyethylene (UHMWPE) blade curve conveyors, leveraging their unique material advantages and outstanding performance, has brought a brand-new solution to the industry. They have become an ideal choice for material conveyance in fields like food processing, pharmaceuticals, chemical engineering, and logistics.

1. Why Choose Ultra-High Molecular Weight Polyethylene (UHMWPE) Material?

Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic engineering plastic with an extremely high molecular weight. Its performance far surpasses that of ordinary plastics and metals, and it is precisely these material properties that have enabled a “qualitative leap” in blade curve conveyors:

- Superior Wear Resistance and Extremely Low Coefficient of Friction: When in long-term contact with granular or powdered materials, the blade edge rarely gets scratched or worn, which significantly extends the equipment’s service life and reduces replacement frequency. Meanwhile, materials are less likely to get stuck or adhere during curved conveyance, making it particularly suitable for sticky materials such as flour, starch, and pharmaceutical powders, thus ensuring smooth conveyance.

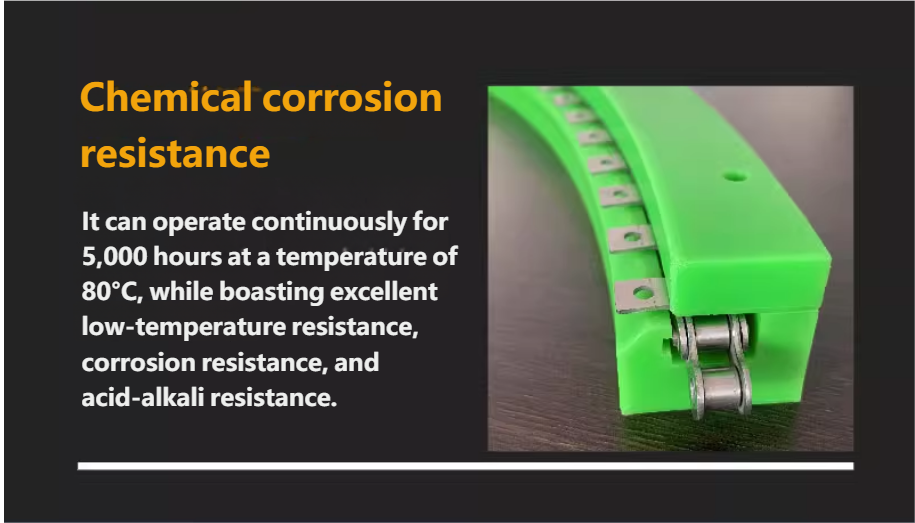

- Excellent Corrosion Resistance: When conveying corrosive materials in the chemical industry, there is no need to worry about equipment rusting. Compared with metal equipment, it is more adaptable to complex working conditions.

- Food-Grade Safety Certification: Non-toxic, odorless, and free from leaching harmful substances, it can be directly used for material conveyance in the food and pharmaceutical industries, eliminating the risk of secondary contamination.

- Lightweight Design: With a density of only 0.93-0.94 g/cm³, it is 1/8 to 1/10 the weight of metal. This makes equipment installation and disassembly more convenient, while also reducing the overall load pressure on the production line and lowering the cost of plant structure modification.

2. Core Advantages of UHMWPE Blade Curve Conveyors

Beyond the inherent properties of the material, our product further meets the actual production needs of enterprises through optimized structural design and functional enhancements:

- Precise Conveyance at Curves, No Material Residue: The blade adopts an arc transition design, combined with a speed-adjustable conveyance system. This prevents materials from piling up or spilling during curved conveyance, effectively reducing material loss. It is particularly suitable for high-precision production scenarios (e.g., conveyance of pharmaceutical capsules and electronic components).

- Long Maintenance-Free Period, Reduced Costs: UHMWPE material does not require regular oiling or rust prevention. It also has high impact resistance and is not easily deformed by material impact. Compared with traditional metal curve conveyors, it can reduce maintenance time and costs by 30%-50% annually.

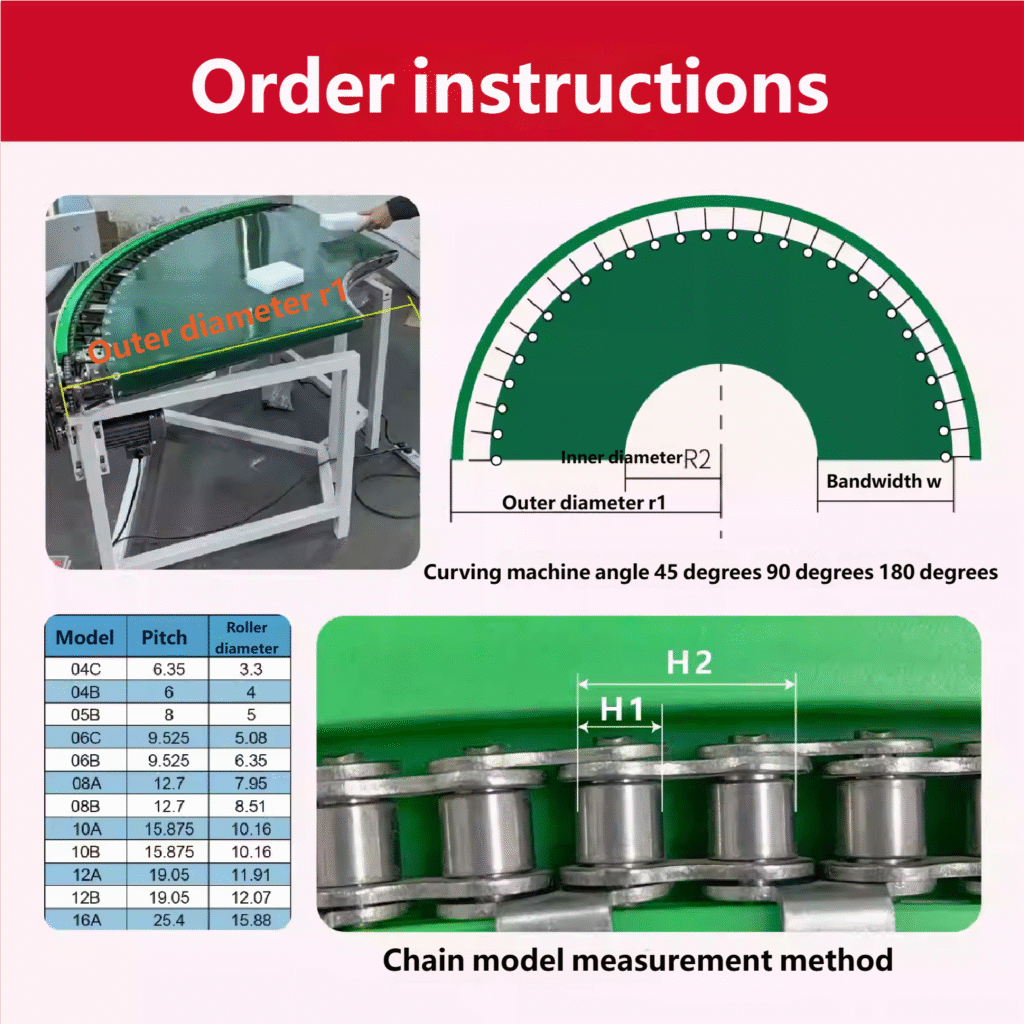

- Customizable to Adapt to Various Production Lines: Customization of equipment size and structure is supported based on conveyance speed and curve angle (90°/180°/customized). Whether for small food processing plants or large chemical enterprises, it can accurately match operational needs.

- Quiet Operation, Improved Working Environment: The material itself has excellent shock absorption and noise reduction properties. The equipment operates at a noise level below 60 decibels, far lower than the 80-90 decibels of metal equipment. This creates a more comfortable production environment for workers and meets the environmental requirements of modern enterprises.

3. Application Scenarios: Covering Diverse Industry Needs from Food to Chemical Engineering

With its versatility, UHMWPE blade curve conveyors have been widely used in multiple industries, addressing the pain points of traditional equipment:

- Food Industry: Used for conveying flour, sugar, biscuits, and meat products. It avoids metal contamination, complies with food hygiene standards, and is easy to clean. It allows quick switching of material types, meeting the needs of multi-category production.

- Pharmaceutical Industry: Conveys tablets, capsules, and pharmaceutical powders. The material is non-toxic and non-static, preventing material adsorption and ensuring drug quality. Meanwhile, it adapts to the strict hygiene requirements of GMP workshops.

- Chemical Engineering Industry: Transports corrosive or abrasive materials such as plastic particles, chemical fertilizers, and dyes. Its chemical corrosion resistance and wear resistance prevent frequent equipment replacement due to material erosion, improving production line stability.

- Logistics Industry: Applied in the curve sections of express sorting and parcel conveyance. The lightweight design can be integrated with automated sorting systems, reducing equipment load, improving sorting efficiency, and ensuring quiet operation that does not disrupt the workshop environment.

Choose us to start an efficient and low-cost new conveying experience.