Pre-Purchase Notice

Product prices do not include shipping costs. Please consult customer service for specific shipping fees.

Shipping costs vary based on quantity, delivery address,and shipping timeframe. We will select the most cost-ef-

fective option according to your specific circumstances to minimize your shopping costs.

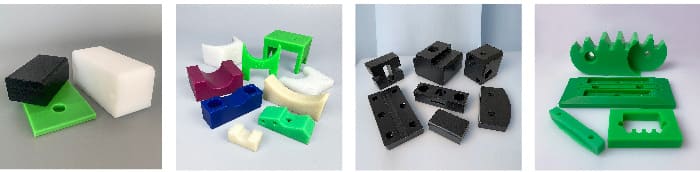

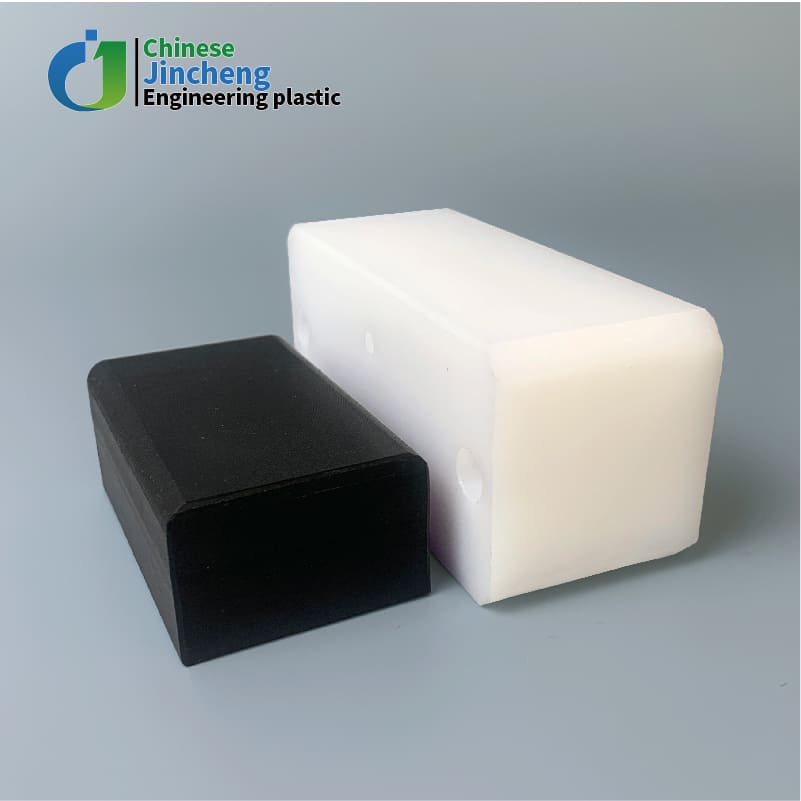

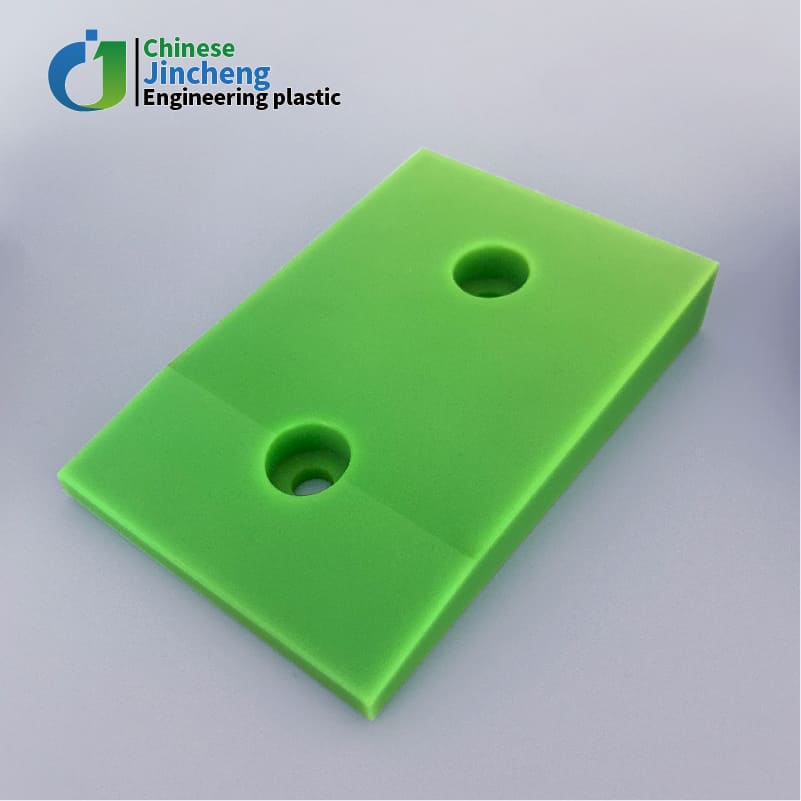

Wear-resistant plastic slider

Reliable processing factory

Professional processing with complete equipment

| The company has been in the machining industry for more than 15 years, and is engaged in the customized processing of special-shaped parts of various materials (wear-resistant,anti-corrosion,sealing,insulation) such as nylon, polymer,polyoxymethylene,polytetrafluoroethylene, etc.; and independently produces plates and rods. |

Product information

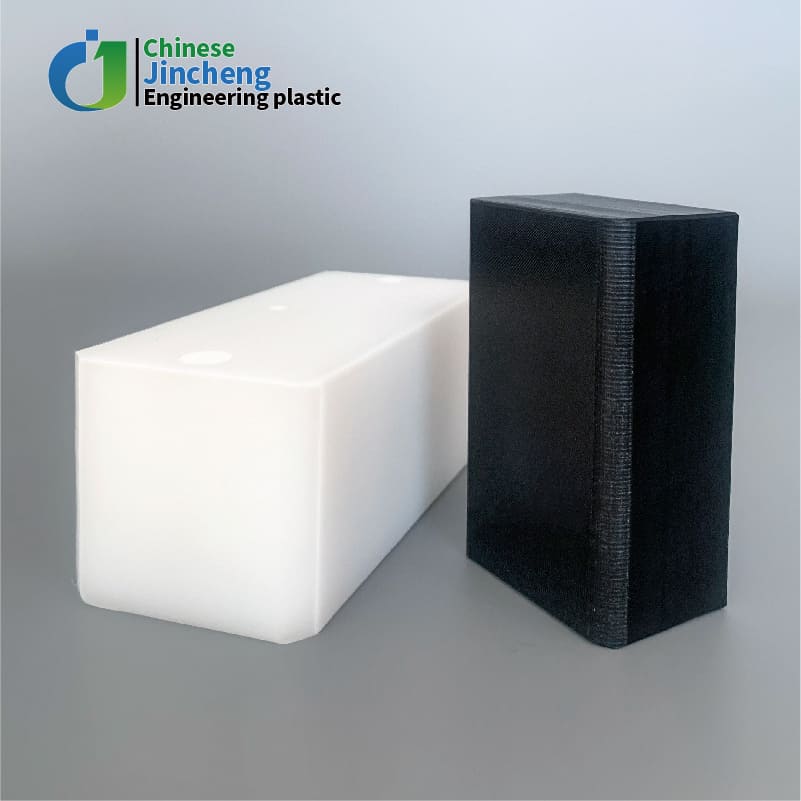

| Material: UHMWPE, nylon, pom, PTFE, PP Color: UHMWPE materials generally have black, white, yellow, green,blue, red, and purple, nylon generally has black, white, yellow, blue, and green, red; POM generally has black and white, PTFE is generally white, PP is generally white. Choose the appropriate raw materials according to needs. Customization method: Processing according to drawings, processing by sending samples Delivery time limit: Generally, it can be delivered from the factory within 3-7 days, and for large quantities, it is discussed separately. Processing methods: Lathe, milling machine, sawing machine, etc.which are reasonably combined according to the characteristics of the product. |

Application scenarios

| The application scenarios of plastic sliders are very extensive, mainly including the paper industry, beverage and food machinery, water treatment, textile machinery, medical equipment and other fields. In the paper industry: Plastic sliders are applied to components such as vacuum box panels, dewatering plates, scrapers, sealing strips, cutting sleeves, etc., and these components play a key role in the papermaking process. In the field of beverage and food machinery: Due to its characteristics of wear resistance, impact resistance, non-stickiness, hygiene, and non-toxicity, plastic sliders are used to manufacture spiral, gear and other components, ensuring hygiene and safety in the beverage and food production process. In terms of water treatment: Plastic sliders are applied in components such as sludge scrapers, screw conveyor sleeves,slurry pump impellers,pump hubs in sewage treatment plants, purifier gears, and sedimentation tank bushings, effectively treating sewage and purifying water quality. In textile machinery: Plastic sliders are used in components such as 36-speed gears, reciprocating baffles and bearing liners with its characteristics of impact resistance, wear resistance and self-lubrication, ensur- ing the efficient operation of textile machinery. In the field of medical equipment: Plastic sliders are used to manufacture human implants, artificial joints, orthopedic surgical instruments and stents, etc.These components have strict requirements for the biocom- patibility and safety of materials, and the characteristics of nylon sliders make it an ideal material choice. Using plastic sliders instead of steel sliders can not only save maintenance costs, but also reduce the pressure of environmental pollution. These application scenarios show the importance and advantages of nylon sliders in multiple industries. |

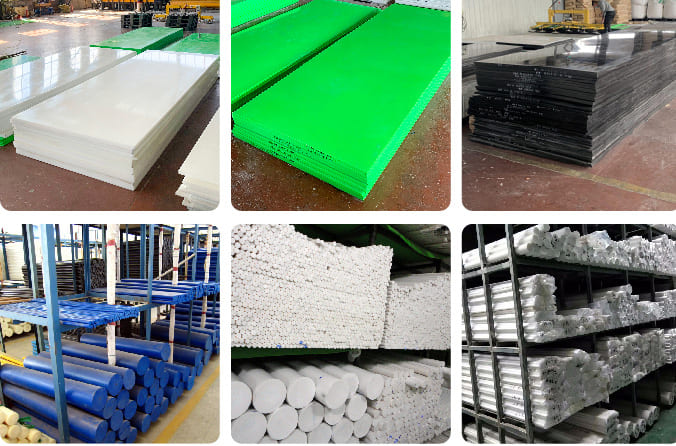

The supply capacity of raw materials

| The company is located in the Hengshui rubber and plastic industry belt. The company has a large amount of commonly used raw materials at its back, and has built a polymer plate production line to meet your various needs |

Product customized development ability

Professional design and drafting personnelOur technical team converts your ideas and |  |

| Neat office environmentA quiet and tidy office environment provides |

Senior process designerExperienced process designers deal with the |  |

Reviews

There are no reviews yet.