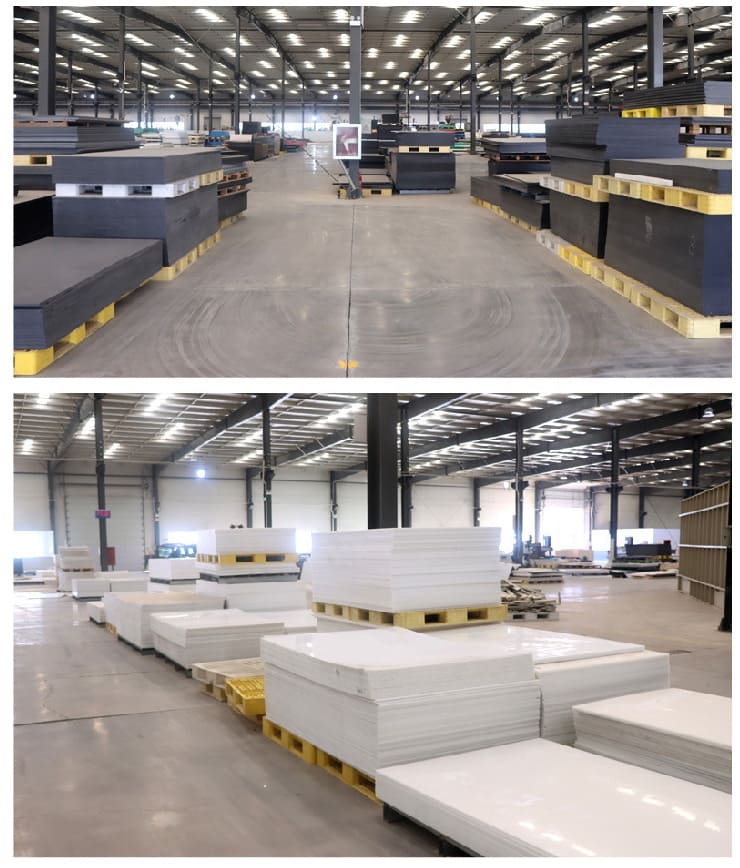

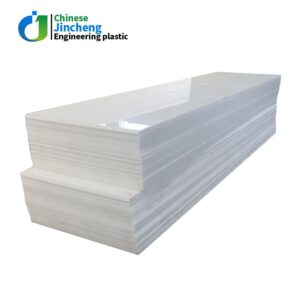

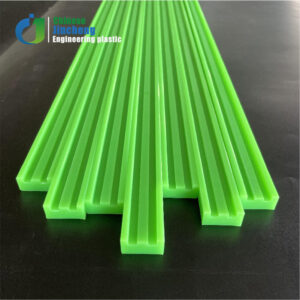

Polypropylene (PP) plate

Product Information

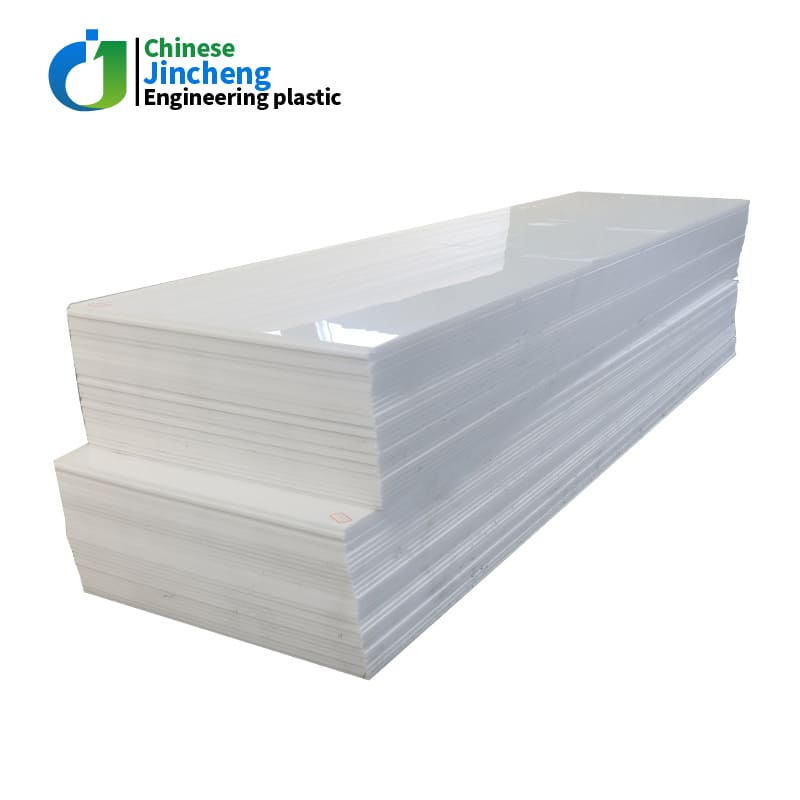

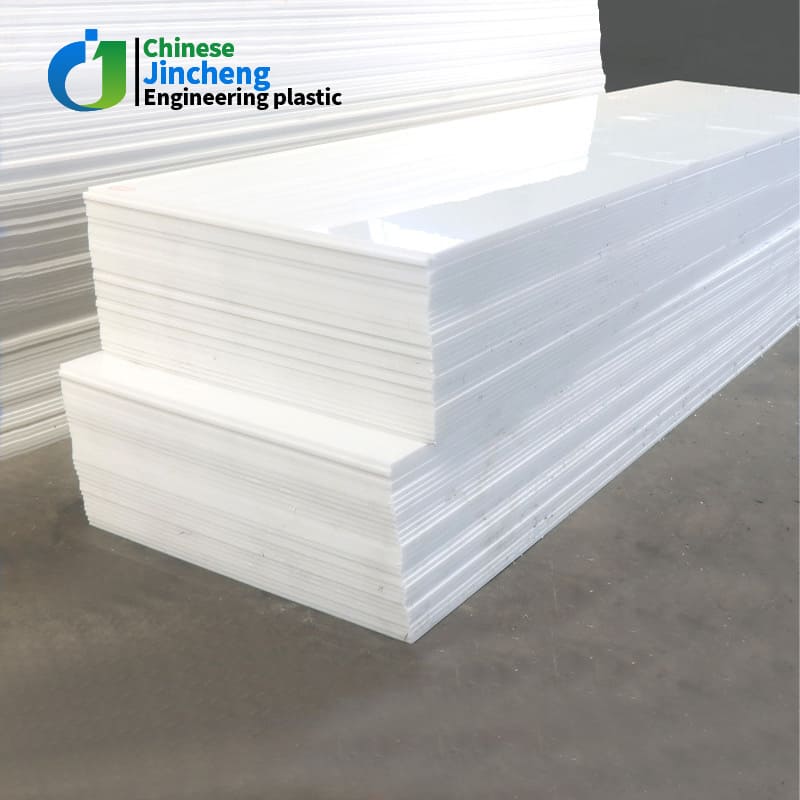

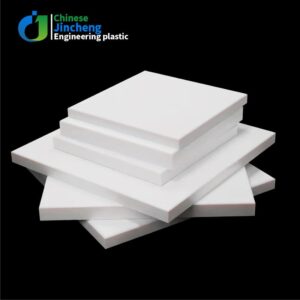

Product thickness:2mm-100mm

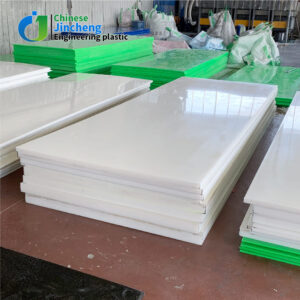

The main colours are green, white, beige, etc.

Recommended specifications: 1500*3000mm, 1220mm*2440mm,1000mm*2000mm

Customized specifications: Width within 2000mm, any length

Main characteristics

Light in weight, uniform in thickness, smooth and flat on the surface,good heat resistance, and high mechanical strength.

Excellent chemical stability and electrical insulation.

Good dimensional stability, low price, rigidity, heat resistance, etc. are all improved to a certain extent compared

to pure PP. And it has good heat resistance, low-temperature impact resistance, anti-corrosion and arc resistance,

and low shrinkage rate.

Odorless and non-toxic.

Easy to weld and firm after welding.

Application fields of PP sheet

It is widely used in chemical containers, machinery, electronics, electrical appliances, food packaging, medicine,

decoration and water treatment, acid and alkali resistant equipment, electroplating equipment, solar photovoltaic

equipment,environmental protection equipment, waste water and waste gas emission equipment, scrubbing towers,

clean rooms, equipment in semiconductor factories and related industries. It is also the preferred material for

manufacturing plastic water tanks.Among them, thick PP plates are widely used in stamping plates, punch bed plates, etc.

Processing methods of PP sheet

Cutting: Tools such as saw blades and knives can be used to cut the PP plate to obtain the required size and shape.

Welding: Methods such as hot air welding and hot air gun welding are used to connect the PP plates together.

Bending: The PP plate is bent to the required angle by means of heating and pressurization.

Engraving: Use an engraving machine to engrave on the PP plate to make various patterns and logos.

Reviews

There are no reviews yet.