Pre-Purchase Notice

Product prices do not include shipping costs. Please consult customer service for specific shipping fees.

Shipping costs vary based on quantity, delivery address,and shipping timeframe. We will select the most cost-ef-

fective option according to your specific circumstances to minimize your shopping costs.

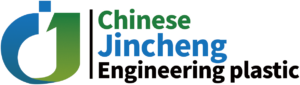

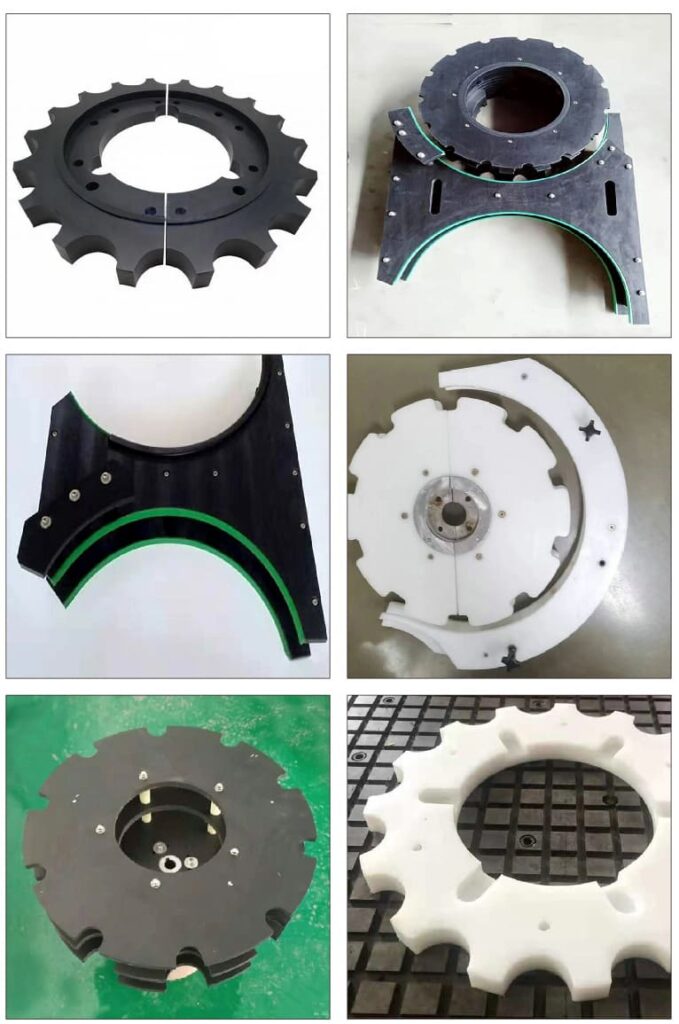

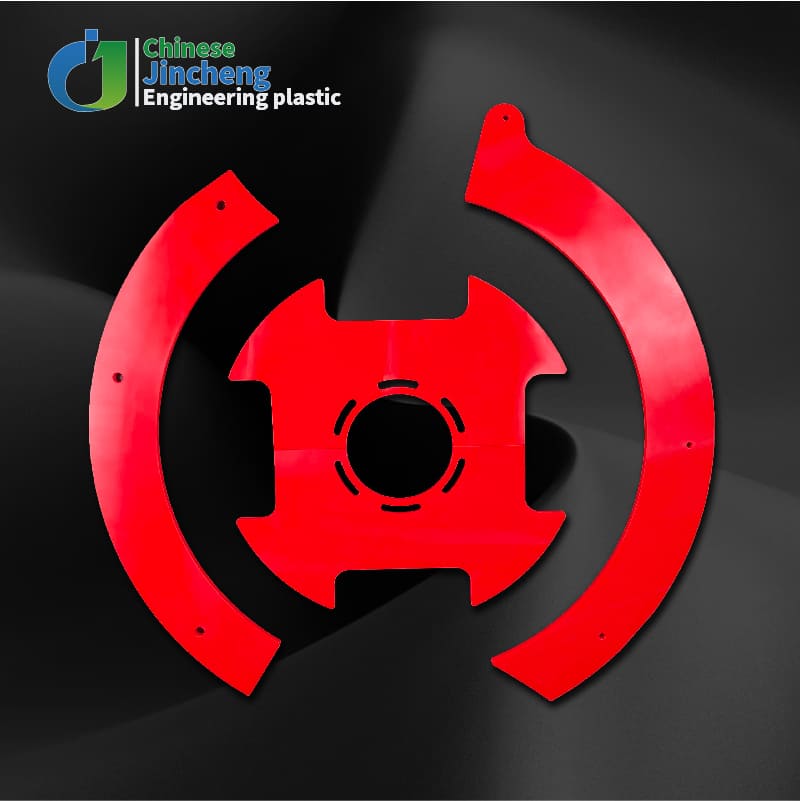

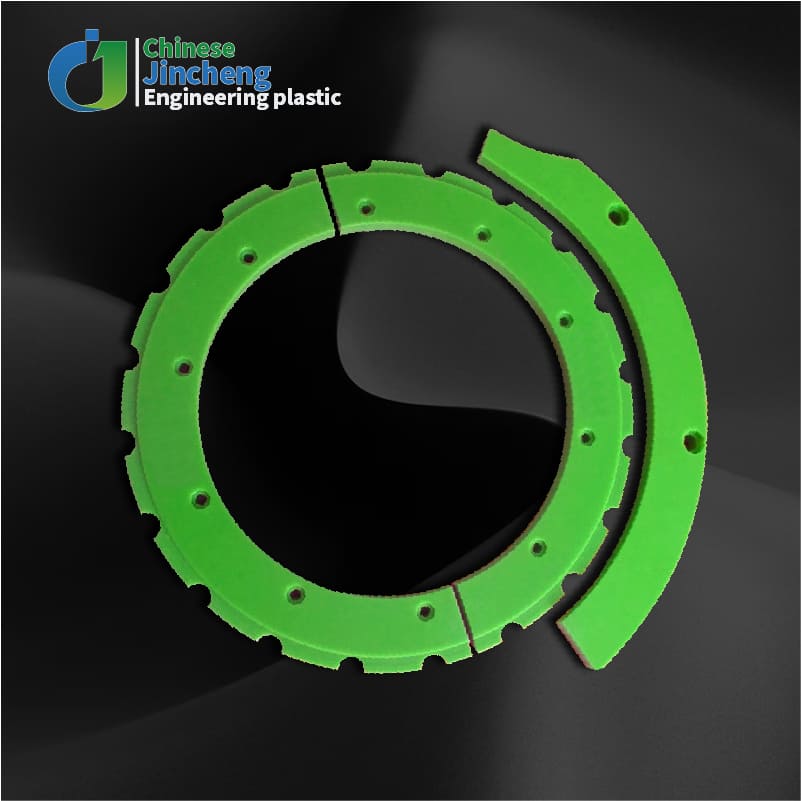

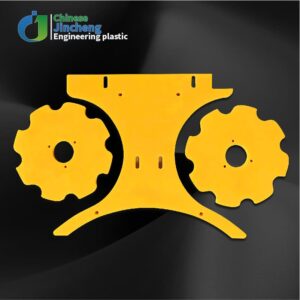

BOTTLE HANDLING CHANGEPARTS

Bottle-pushing star wheel

Reliable processing factory

Professional processing with complete equipment

Product information

| Name: Bottle handling changeparts/Bottle-pushing star wheel Material: UHMWPE. Color: UHMWPE materials generally have black, white, yellow,green,blue, red, and purple; Customization method: Processing according to drawings, processing by sending samples Delivery time limit: Generally, it can be delivered from the factory within 3-7 days, and for large quantities, it is discussed separately. |

Product features and applications

| Precise Separation and Positioning of Bottle-Separating Wheels The precise separation and positioning of bottle-separating wheels mainly rely on their special structural design and operating mechanism. Bottle-separating wheels usually consist of multiple evenly distributed teeth or grooves, and the size and spacing of these teeth or grooves are precisely calculated to accommo- date bottles of different specifications. During operation, the rotation speed and angle of the bottle- separating wheel can be precisely controlled so that the bottles can accurately fall into the corresponding teeth or grooves to achieve separation and positioning. For example, in some high-precision production lines, advanced sensors and control systems are adopted in the bottle-separating wheels.which can monitor the position and status of the bottles in real-time and adjust the operating parameters of the bottle-separating wheel in time according to the feedback information to ensure the accuracy of separation and positioning. |

| Speed Adjustment and Adaptability of Bottle-Separating Wheels The speed adjustment function of bottle-separating wheels makes them highly adaptable. By changing the rotational speed of the driving motor or using a variable speed device, the bottle-separating wheel can work at different production speeds. Whether it is a low-speed manual production line or a high-speed automated production line, the bottle-separating wheel can be adjusted according to actual needs. In addition, the bottle-separating wheel can also adapt to changes in different production line layouts and process requirements. For example, when the production line needs to switch products or improve the process, the bottle-separating wheel can quickly adapt to the new production requirements through simple adjustments and modifications, reducing the downtime and adjustment costs of the production line. |

| The Role of Bottle-Separating Wheels in Beverage Filling Production Lines In beverage filling production lines, the role of bottle-separating wheels is very significant. It can quickly and accurately separate the continuously conveyed bottles and make them move forward at a uniform spacing and a stable speed. This not only ensures the continuity and stability of the filling process but also avoids collisions and blockages between bottles. At the same time, the bottle-separating wheel can also flexibly adjust the conveying speed of the bottles according to the working rhythm of the filling equipment to make the filling operation more efficient and precise. For example, for high-speed filling production lines, the bottle-separating wheel can separate bottles at an extremely fast speed to meet production needs;while for products that require high-precision filling, the bottle-separating wheel can control the position of the bottles more precisely to ensure the accuracy of the filling volume.To sum up, bottle-separating wheels play an important role in various production lines. Their characteristics such as precise separation, positioning, speed adjustment and adaptability provide strong support for improving production efficiency,ensuring product quality and reducing production costs. |

Product display

Reviews

There are no reviews yet.