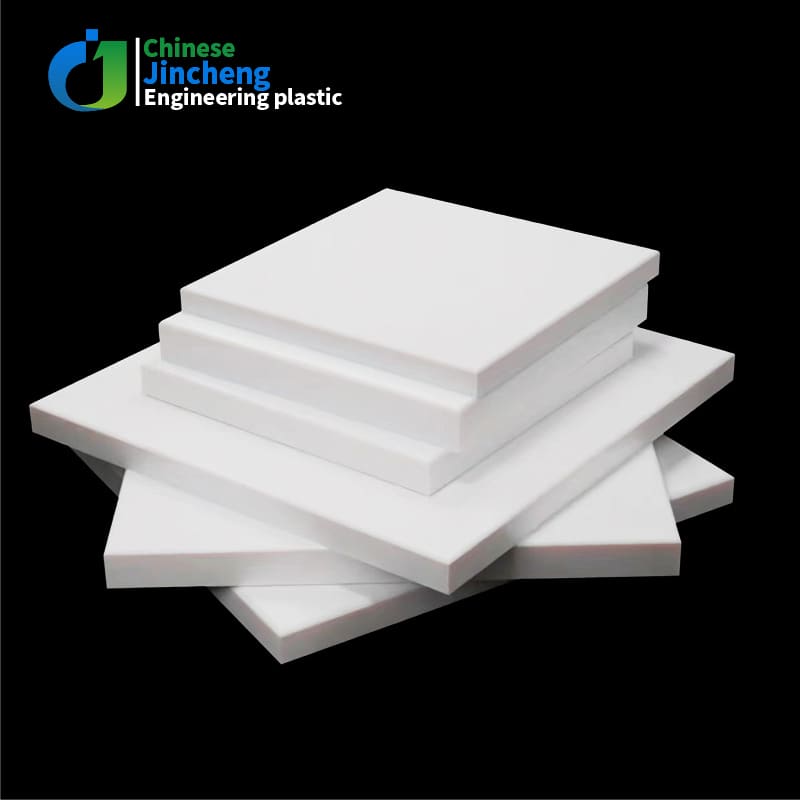

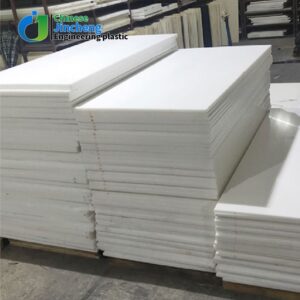

Polytetrafluoroethylene (PTFE) sheet

Product Information

Polytetrafluoroethylene (PTFE) plate is made by molding polytetrafluoroethylene resin at room temperature,

followed by sintering and cooling.

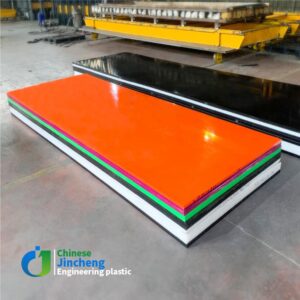

Color:white

Size: Customizable

Thickness: 0.5-120mm

Technical Parameter

| project | Company | Indicator |

| density | g/cm³ | 2.1-2.3 |

| bending strength | Mpa | 11-14 |

| tensile strength | Mpa | 21-28 |

| friction coefficient | / | 0.04 |

| Water absorption rate | % | <0.03 |

| Dielectric strength | KV/mm | 10 |

| Usage temperature | ℃ | -180~260 |

| Melting temperature | ℃ | 325 |

Polytetrafluoroethylene (PTFE)sheet features

| High temperature resistance |

| Low temperature resistance |

| Acid and alkali resistant |

| Climate resistant |

| High lubrication |

| Non adhesive |

| Non toxic |

| Insulation properties |

High temperature resistance:The operating temperature can reach 250℃.

Low temperature resistance:It has good mechanical toughness; even when the temperature drops to -196℃,

it can still maintain an elongation of 5%.

Corrosion resistance:It shows inertness to most chemicals and solvents, and can withstand strong acids, strong

alkalis, water and various organic solvents.

Weather resistance:It has the best aging life among plastics.

High lubrication:It has the lowest friction coefficient among solid materials.

Non-adhesion:It has the smallest surface tension among solid materials and does not adhere to any substances.

The mechanical properties of it have a very small friction coefficient, only 1/5 of that of polyethylene.

This is an important feature of the perfluorocarbon surface. Also, due to the extremely low intermolecular force

of the fluorine-carbon chain, polytetrafluoroethylene is non-adhesive.

Non-toxic:It has physiological inertness and has no adverse reactions when implanted in the body as artificial

blood vessels and organs for a long time.

Electrical performance:The dielectric constant and dielectric loss of polytetrafluoroethylene are very low within

a wide frequency range, and the breakdown voltage, volume resistivity and arc resistance are all relatively high.

Radiation resistance:The radiation resistance of polytetrafluoroethylene is poor (104 rads). After being exposed

to high-energy radiation, it causes degradation, and the electrical and mechanical properties of the polymer

decrease significantly. Applications Polytetrafluoroethylene can be processed by compression or extrusion

molding, it can also be made into an aqueous dispersion for coating, impregnation or made into fibers.

Polytetrafluoroethylene is widely used in atomic energy, aerospace, electronics, electrical, chemical,mechanical,

instrumentation, architectural, textile, food and other industries as a material resistant to high and low temperatures,

corrosion, insulation materials,anti-stick coatings, etc.

Atmospheric aging resistance:Radiation resistance performance and low permeability.Long-term exposure to

the atmosphere, the surface and performance remain unchanged.

Non-flammability:The limited oxygen index is below 90.

Acid and alkali resistance:Insoluble in strong acids, strong alkalis and organic solvents.

Oxidation resistance:Can withstand the corrosion of strong oxidants.

Acid and alkali property:It is neutral.

The mechanical properties of polytetrafluoroethylene are relatively soft. It has a very low surface energy.

Application fields of PTFE sheet

Polytetrafluoroethylene plates are widely used in various fields. The following are some main uses of

polytetrafluoroethylene plates:

Electrical industry: In the electrical industry, polytetrafluoroethylene plates are used as insulation layers for

power and signal lines, as corrosion-resistant and wear-resistant materials.They can be made into films, tubes,

plates, rods, bearings, gaskets, valves, and linings for chemical pipelines, pipe fittings, equipment containers, etc.

Chemical industry: In the chemical industry, polytetrafluoroethylene plates are used to manufacture equipment

such as pipelines and seals to prevent the erosion of equipment by acids, alkalis and other chemicals. It can also

be used as a diaphragm in reactors or as a lining for agitators to protect internal components from wear.

Food industry: Due to its non-toxic, high insulation and non-adhesive properties, polytetrafluoroethylene

plates meet food-grade requirements and can be used for food equipment accessories, such as the inner layer

of easy-to-clean water pipes.

Medical and scientific research: In the fields of medical and scientific research, polytetrafluoroethylene plates

can be used as containers for ultra-pure chemical analysis and the storage of various acids, alkalis and

organic solvents.

Oil and gas industry: In the oil and gas industry, polytetrafluoroethylene plates are used for leak prevention

during oil well drilling, to reduce mud loss, and as films for lubricating materials, etc.

Processing methods of polytetrafluoroethylene plates

Molding method: It is by putting polytetrafluoroethylene resin into a mold and then sintering it at high

temperature and high pressure to make it formed.

Pushing method: Involves heating and melting polytetrafluoroethylene resin using specific equipment and

then forming it.

Machining method: Such as using equipment like lathes and milling machines for processing, suitable for more

precise forming requirements.

Reviews

There are no reviews yet.