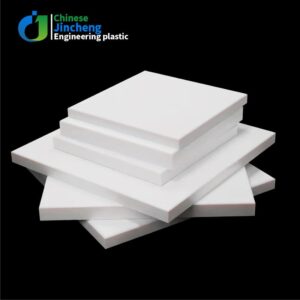

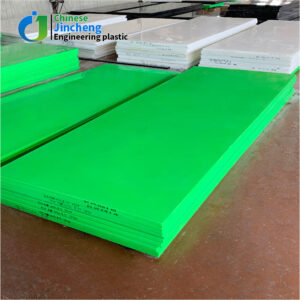

Polyethylene (PE) sheet

Product information

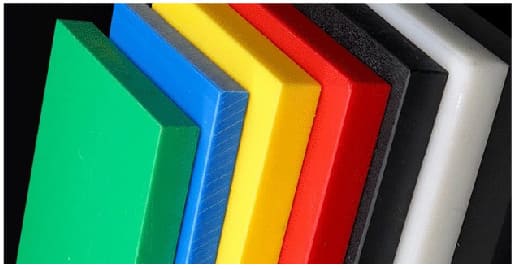

Color

Common colors are black, white, yellow, green, blue and red.

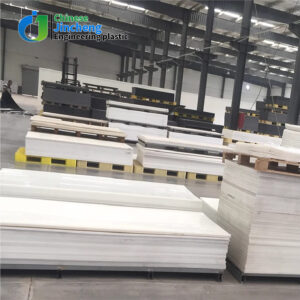

size

Spot size:

1000*2000,thickness 3-150 millimeters, 1220*2440,thickness 3-30 millimeters

Custom size: The maximum width is 3000mm; arbitrary length;thickness 3 -150 millimeters

The characteristics of polyethylene plates

Corrosion resistance

It has good chemical corrosion resistance and can resist the erosion of various chemical substances

such as acids, alkalis, and salts. This enables PE plates to be widely used in fields such as chemical

engineering and environmental protection.

Wear resistance

The surface hardness is relatively high and it has good wear resistance.In some occasions that need

to withstand friction and wear, such as conveying pipelines and the inner lining of material bins,

PE plates can effectively reduce wear and extend the service life of equipment.

Impact resistance

It has a relatively high impact strength and can withstand a certain degree of external force impact

without being easily cracked. This makes PE plates have good application prospects in some occasions

that need to withstand impact loads,such as protective fences and packaging materials

Low friction coefficient

The surface is smooth and the friction coefficient is low. This enables PE plates to effectively improve

the operating efficiency of equipment in some occasions that need to reduce frictional resistance,

such as sliding guides and conveying chains.

Electrical insulation

It has good electrical insulation performance and can prevent current leakage and electric shock

hazards to a certain extent. This enables PE plates to be widely used in the field of electrical insulation.

Application fields of PE plates

Chemical industry

Used to make the inner lining, pipelines, valves and other components of chemical equipment, which

can effectively resist chemical corrosion and increase the service life of the equipment.

Environmental protection industry

Can be used as the inner lining of sewage treatment equipment, anti-seepage materials for landfill sites,

etc., with good corrosion resistance and sealing performance.

Machinery manufacturing

Used to make sliding guides, bearing housings, gears and other components of mechanical parts,

with good wear resistance and low friction coefficient.

Packaging industry

Can be used to make various packaging materials, such as plastic bags, plastic films, plastic bottles, etc.,

with good flexibility and impact resistance.

Construction industry

Used to make construction formworks, floors, wall panels and other materials, with good wear resistance

and corrosion resistance.

farm mechanical equipment Food and Medicine

electronics industry High end circuit board Photovoltaic equipment

equipment

Ventilation tower Market cutting board Fishing boats and

plastic boats

Water tank breeding box Acid and alkali resistant Cutting machine cutting plate

chemical water tank

Processing methods that can

be adopted for PE plates

Cutting

Equipment such as sawing machines and cutting machines can be used to cut PE plates to meet the needs

of different sizes.

Welding

Methods such as hot plate welding and hot air welding can be used to weld PE plates into containers,

pipelines and other shapes of various kinds.

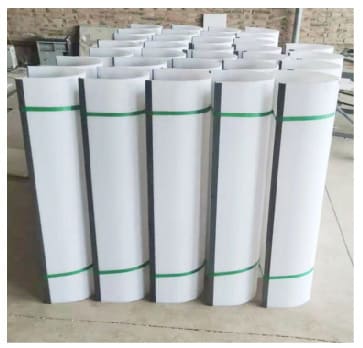

Bending

Through heating and pressurizing, PE plates can be bent into shapes of different angles for making

various structural components.

Engraving

Equipment such as CNC engraving machines can be used for engraving processing on PE plates to make

various patterns and text identifications.

Reviews

There are no reviews yet.