Pre-Purchase Notice

Product prices do not include shipping costs.Please consult customer service for specific shipping fees.

Shipping costs vary based on quantity, delivery address,and shipping timeframe. We will select the most cost-ef-

fective option according to your specific circumstances to minimize your shopping costs.

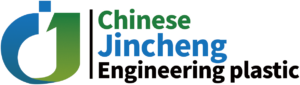

Nylon bushing

Reliable processing factory

Professional processingwith complete equipment

Precise size High-precision processing

Product information

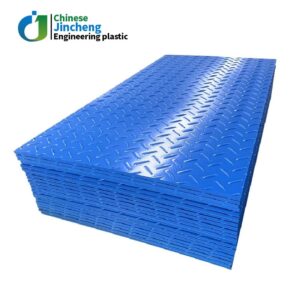

| Material: UHMWPE, nylon, pom, PTFE. Color: UHMWPE materials generally have black, white, yellow, green,blue, red, and purple,;nylon generally has black, white, yellow, blue, and green, red; POM generally has black and white; PTFE is generally white; Choose the appropriate raw materials according to needs. Customization method: Processing according to drawings, processing by sending samples Delivery time limit: Generally, it can be delivered from the factory within 3-7 days, and for large quantities, it is discussed separately. Processing methods: Lathe, milling machine, sawing machine, etc.,which are reasonably combined according to the characteristics of the product. |

Application scenarios

Nylon shaft sleeves have many functional characteristics:Wear resistant, with good self smoothing effect, can still operate effectively without or with little oil, and the wear resistance is usually 2-8 times that of certain alloys and copper; Good durability, with excellent fatigue resistance, high mechanical strength, low noise, and impact resistance. It can reduce load to evenly distribute pressure, reduce operational noise, and improve operational speed; Low requirements for the working environment, even with abrasive impurities, can work normally to avoid shaft biting and damage; Stable chemical properties, not strict requirements for lubricating oil, can use lubricating grease; Lightweight, about one eighth that of copper, can reduce material costs and strength; It can make the equipment more durable, extend the usage time by 2-8 times compared to the original, help improve the working power of the equipment, reduce enterprise costs, minimize equipment maintenance frequency and downtime losses; Reduced cutting and processing costs, with high elasticity and plasticity, no need for high tolerance requirements like metals, and the inner and outer diameters can be processed with 5-6 levels of precision. |

Application scope of nylon shaft sleeveIn the automotive industry, nylon bushings are used in engines, transmissions, steering wheels, brake systems, doors, windows, and other parts to lubricate, reduce noise and vibration, and extend service life. In the field of agricultural machinery, nylon shaft sleeves can be applied to various transmission components of agricultural machinery, improving the reliability and stability of the machinery. In the field of construction machinery, nylon shaft sleeves can also be seen in key parts of equipment such as excavators and loaders. They can withstand large loads and impacts, and have good wear resistance and self-lubricating properties. In shipbuilding, nylon shaft sleeves are used in the propulsion system, servo system, etc. of ships, which can adapt to the harsh conditions of marine environments. Nylon shaft sleeves play an important role in various fields such as electronic instruments, printing machinery, textile machinery, packaging equipment, food machinery, chemical equipment, medical devices, mining machinery, etc. For example, in printing machinery, nylon bushings are used to support and guide the printing drum, ensuring printing quality; In mining machinery, nylon shaft sleeves are used for equipment such as crushers and conveyors to improve their wear resistance and service life. |

Size selection of nylon shaft sleeveChoosing the appropriate size of nylon shaft sleeve is the key to ensuring smooth mechanical assembly and operation. The size selection of nylon shaft sleeves requires comprehensive consideration of multiple factors. Firstly, the diameter of the shaft. The inner diameter of the nylon shaft sleeve should closely match the diameter of the shaft, as being too large or too small can affect the installation and use of the shaft sleeve. The selection of outer diameter should be based on the size of the installation hole to ensure that the shaft sleeve can be correctly installed and tightly fitted. The determination of length should be based on the installation space and the required load, ensuring sufficient support length while avoiding instability or increased friction caused by being too long or too short. Wall thickness is also an important parameter that depends on the load and stress it is subjected to. Generally, the thicker the wall thickness, the higher the strength and stiffness of the shaft sleeve, but it also increases cost and weight. In addition, it is necessary to consider tolerances and choose appropriate nylon shaft sleeve tolerances to ensure that the fit clearance between the shaft sleeve and the shaft and hole is appropriate, neither too tight to cause jamming nor too loose to cause movement. When choosing the size, it is recommended to refer to relevant standards and specifications, or consult professional engineers to ensure that the most suitable nylon shaft sleeve size is selected. |

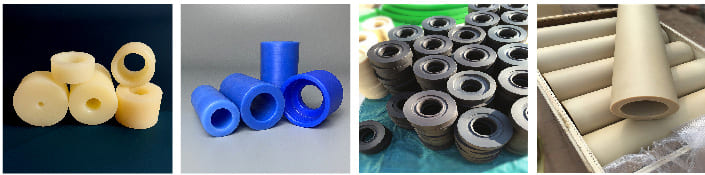

The supply capacity of raw materials

| The company is located in the Hengshui rubber and plastic industry belt. The company has a large amount of commonly used raw materials at its back, and has built a polymer plate production line to meet your various needs. |

Product customized development ability

Professional design and drafting personnelOur technical team converts your ideas and |  |

| Neat office environmentA quiet and tidy office environment provides |

Senior process designerExperienced process designers deal with the |  |

Reviews

There are no reviews yet.