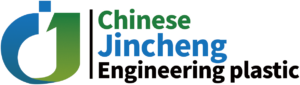

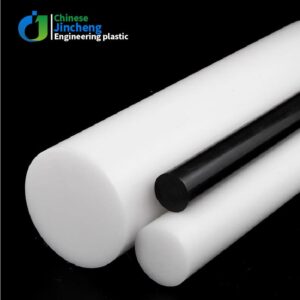

Polyethylene (HDPE) rod

Polyethylene (PE) rods are a kind of rod-shaped material made

from polyethylene resin

Product information

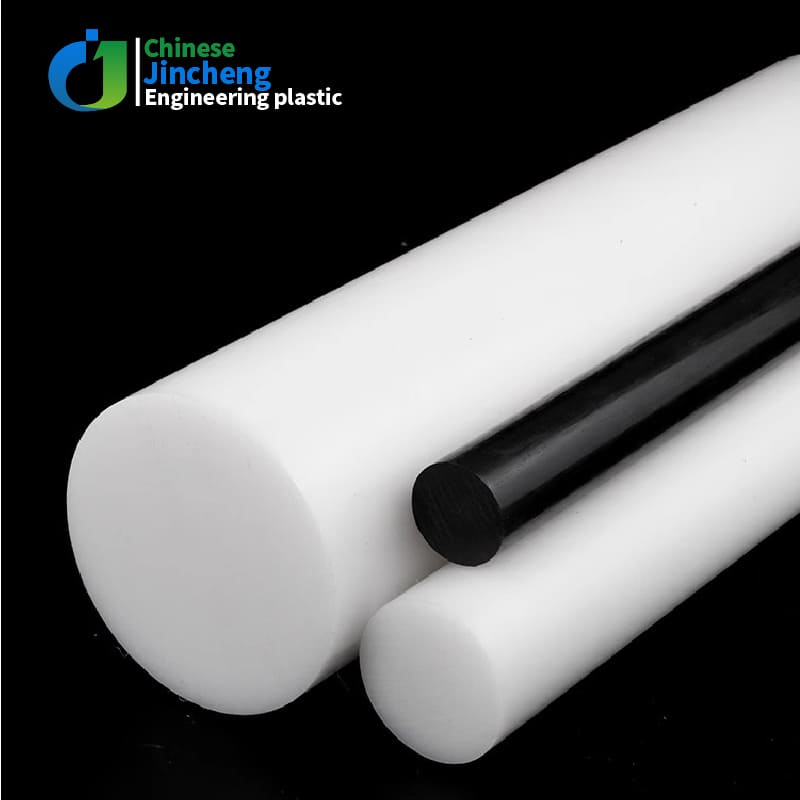

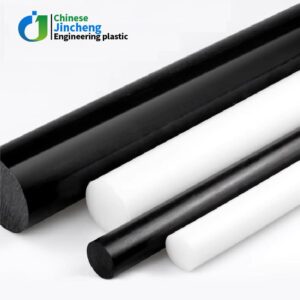

Name: (HDPE) rod

Material: Polyethylene

Color: Black, White

Diameter: 15mm-200mm, commonly used include 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90

100, 110, 120, 130, 145, 150, 160, 170, 180, 200

Length: 1 meter

HDPE rod Characteristics

Corrosion resistance

It has excellent chemical corrosion resistance and can resist the erosion of various acids, alkalis,

salts and organic solvents. This enables PE rods to be widely used in fields such as chemical

engineering and environmental protection, and can be used to make components of equipment

such as pipelines, containers and valves.

Wear resistance

The surface hardness is relatively high and it has good wear resistance. In some occasions that need to

withstand friction and wear, such as conveying systems and mechanical parts, PE rods can effectively

reduce wear and extend the service life of the equipment.

Impact resistance

It has a relatively high impact strength and can withstand a certain degree of external force impact

without being easily cracked. This makes PE rods have good application prospects in some occasions that

need to withstand impact loads, such as protective devices and packaging materials.

Low friction coefficient

The surface is smooth and the friction coefficient is low. This enables PE rods to effectively improve the

operating efficiency of the equip ment in some occasions that need to reduce frictional resistance.

such as sliding guides and bearings.

Electrical insulation

It has good electrical insulation performance and can prevent current leakage and electric shock hazards

to a certain extent. This enables PE rods to be widely used in the field of electrical insulation and can

be used to make insulation layers of wires and cables and components of electrical equipment.

Application fields

Machinery manufacturing

Can be used to make various mechanical parts, such as bearings, gears and sliders.The wear resistance

and low friction coefficient of PE rods can effectively reduce wear and friction in mechanical transmission

systems, and improve the operating efficiency and service life of the equipment.

Chemical industry

Used to make components of chemical equipment, such as pipelines,valves and pump bodies. The

corrosion resistance of PE rods enables them to operate stably in harsh chemical environments and

prevent the equipment from being eroded by chemical substances.

Food processing

Due to the characteristics of being non-toxic,odorless, corrosion-resistant and easy to clean of PE rods,

they can be used to make components of food processing equipment, such as conveying pipelines,

hoppers and mixers.

Environmental protection engineering

Can be used to make components of environmental protection equipment, such as pipelines and filters

of sewage treatment equipment. The corrosion resistance and wear resistance of PE rods enable them

to operate stably in harsh environmental protection engineering environments and improve the service

life of the equipment.

Construction industry

Can be used to make components of construction materials, such as sealing strips of doors and windows

and backing plates of floors. The flexibility and corrosion resistance of PE rods enable them to be widely

used in the construction industry and improve the performance and service life of construction materials.

Processing methods

Cutting

Equipment such as sawing machines and cutting machines can be used to cut PE rods to meet the

needs of different sizes. During the cutting process, appropriate cutting tools and cutting parameters

should be selected to ensure the flatness and accuracy of the cutting surface.

Drilling

Equipment such as drilling machines can be used to drill PE rods to meet the needs of installation

and connection. During the drilling process, appropriate drill bits and drilling parameters should

be selected to ensure the accuracy and quality of the drilling.

Turning

Equipment such as lathes can be used for turning processing of PE rods to meet the needs of

different shapes and sizes. During the turning process, appropriate cutting tools and turning

parameters should be selected to ensure the flatness and accuracy of the processed surface.

Welding

Methods such as hot plate welding and hot air welding can be used to weld PE rods into structural

components of various shapes. During the welding process, appropriate welding parameters and

welding materials should be selected to ensure the welding quality and strength.

In conclusion, polyethylene (PE) rods have characteristics such as corrosion resistance,wear

resistance,impact resistance, low friction coefficient and electrical insulation, and are widely used in

fields such as machinery manufacturing, chemical industry, food processing, environmental protection

engineering and construction. At the same time, through different processing methods, PE rods can

be processed into products of various shapes and sizes to meet different needs.

Reviews

There are no reviews yet.