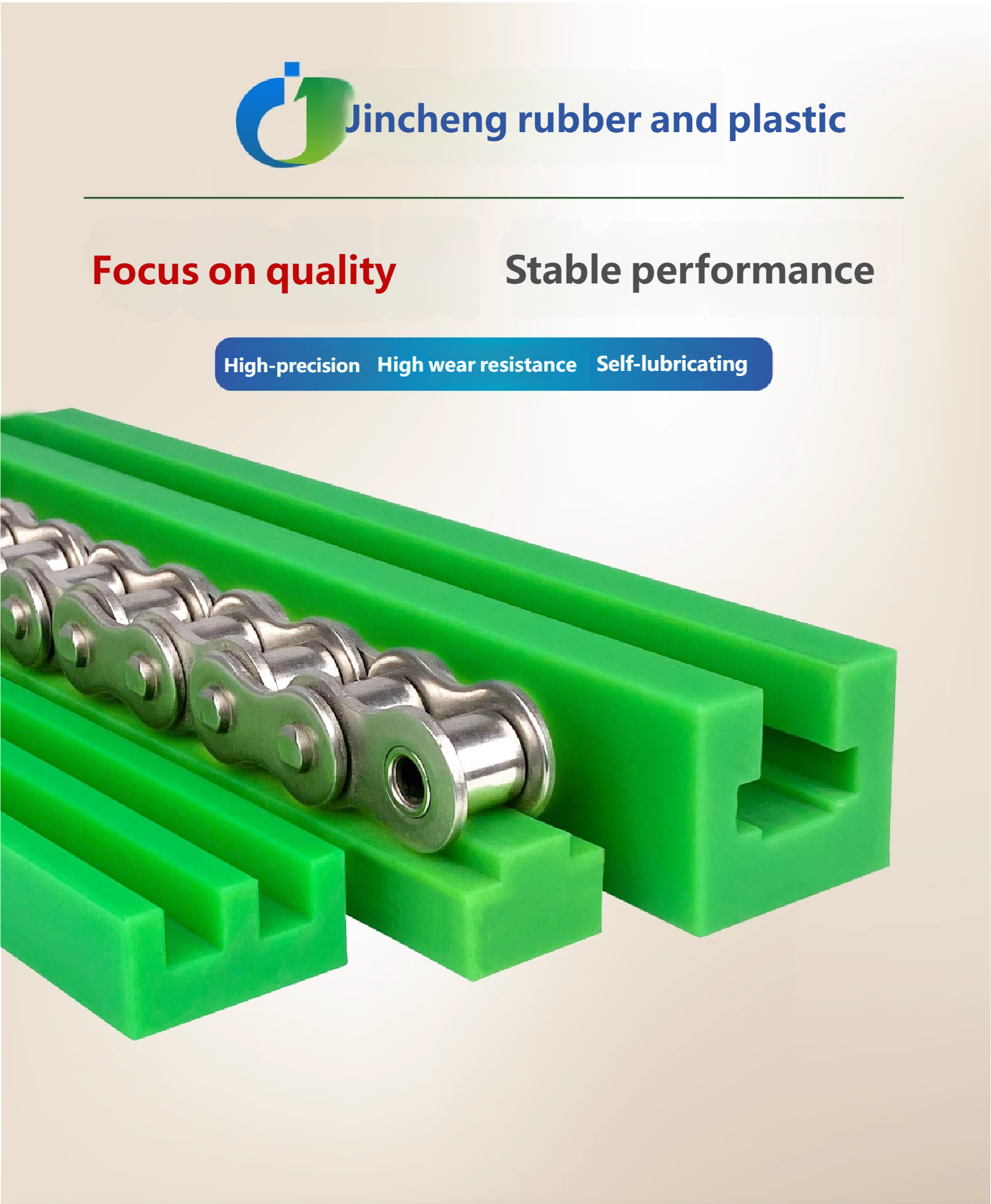

Ultra-High Molecular Weight Polyethylene Chain Guide Wear Strips: The New Favorite in Industry

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged prominently in numerous fields due to its outstanding comprehensive properties. This linear polyethylene, with a molecular weight exceeding 1.5 million and a density of only 0.93 – 0.94g/cm³, exhibits remarkable strength and toughness. It perfectly inherits the many advantages of UHMWPE material, bringing a revolutionary change to chain systems.

(I) Wear Resistance Data Comparison

The wear resistance of UHMWPE chain guide wear strips is truly excellent, and its advantages are evident through a set of data comparisons. Under the same working conditions, such as in high-friction environments like dust conveying chains, if the relative wear resistance of carbon steel chain guides is set to 1, that of stainless steel chain guides is 3 – 4, ordinary polyethylene chain guides is 5 – 8, while the relative wear resistance of UHMWPE chain guides is as high as 7 – 10. It is 7 – 10 times that of carbon steel, 3 – 5 times that of stainless steel, and 3 – 5 times that of ordinary polyethylene. In terms of actual service life, carbon steel chain guides in dust conveying chains usually need to be replaced within one year; stainless steel chain guides can be used for 3 – 4 years; ordinary polyethylene chain guides can last for 5 – 8 years; UHMWPE chain guides, however, can operate stably for 7 – 10 years or even longer. This means that the use of UHMWPE chain guides can significantly reduce the frequency of equipment maintenance and guide replacement due to wear, minimize downtime, and improve production efficiency.

(II) Unique Wear-Resistant Characteristics

UHMWPE chain guide wear strips also possess the unique characteristic of “becoming more wear-resistant as they wear”, which is quite rare among materials. When subjected to impact loads, its molecular chains undergo elastic deformation like springs, thereby absorbing energy. During this process, surface wear not only does not increase but also decreases. At the moment when the chain starts and stops, a large impact force is generated. Guides made of ordinary materials are prone to rapid wear under such impacts, while UHMWPE chain guides can maintain excellent wear resistance by virtue of this characteristic, stably supporting the operation of the chain and providing a solid guarantee for the stable operation of equipment.

(III) Analysis of Factors Affecting Wear Resistance

- Load Magnitude: It is one of the key factors. Within a reasonable load range, usually ≤ 10MPa, its wear resistance performance is stable; once the load exceeds the limit, the material will undergo plastic deformation due to being unable to withstand excessive pressure, which in turn leads to increased wear.

- Friction Speed: It cannot be ignored either. In the low to medium speed range, i.e., ≤ 5m/s, the wear resistance is optimal; when the friction speed exceeds 10m/s, the heat generated by high-speed friction will soften the guide surface, and the degree of wear will increase slightly.

- Environmental Medium: It also affects the wear resistance of the guide. In dry and dusty environments, the wear resistance of UHMWPE chain guides is significantly better than that of metals; under lubricating conditions, its inherent self-lubricating property can further reduce wear without the need for additional lubricants. This not only reduces costs but also avoids pollution problems caused by lubricants.

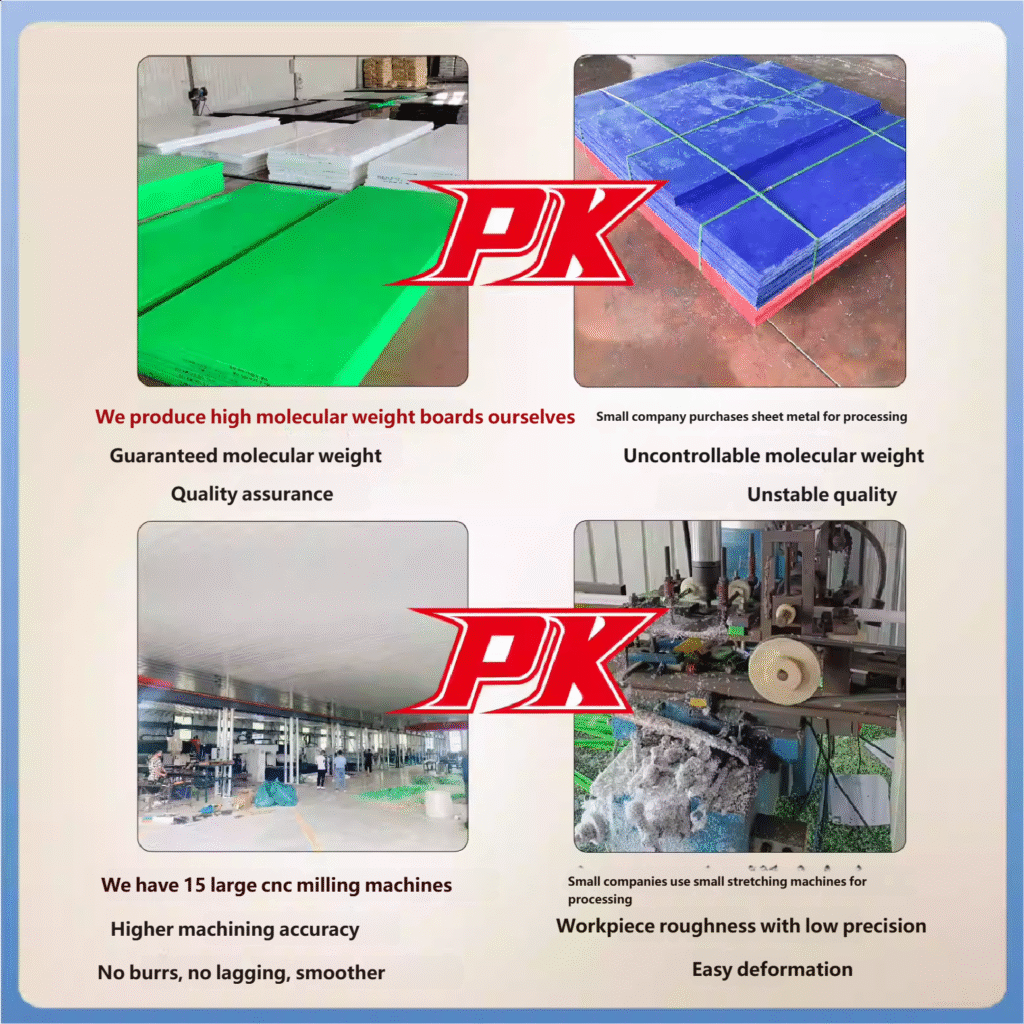

- Surface Roughness: It is closely related to wear resistance. UHMWPE guides with high processing precision have a smoother surface, resulting in more uniform frictional contact with the chain and slower wear. Therefore, in the production and processing process, strictly controlling the surface roughness can better exert its wear-resistant performance.

Beyond Wear Resistance: More Advantages

(I) Strong Impact Resistance

The impact resistance of UHMWPE chain guide wear strips is equally outstanding. Its performance is particularly prominent in low-temperature environments; even in liquid nitrogen at -200°C, it can still maintain excellent toughness without brittle fracture. Its impact strength is far higher than that of nylon and ordinary polyethylene, ranking among the top in plastic materials. It is 2 – 3 times that of PC material and 3 – 5 times that of ABS material. At the feed inlet of crushers in the mining industry, chain guides need to withstand the high-speed impact of ores. UHMWPE chain guides can effectively absorb impact energy, protect the chain and equipment, reduce damage caused by impact, and ensure the stable operation of equipment. In large-scale loading and unloading equipment at ports, it can also cope with harsh working conditions, ensure the normal operation of equipment, and greatly reduce equipment maintenance costs and downtime.

(II) Chemical Corrosion Resistance

Chemical corrosion resistance is another major advantage of UHMWPE chain guide wear strips. It has strong resistance to acids, alkalis, salts, and most organic solvents, and performs excellently in corrosive working conditions in industries such as chemical engineering and electroplating. In chemical raw material conveying chains, common chemical reagents such as hydrochloric acid, sulfuric acid, and sodium hydroxide cannot corrode it. In electroplating production lines, chain guides can remain stable and not be corroded even when in long-term contact with electroplating solutions containing heavy metal ions, ensuring the normal operation of the chain and extending the service life of the equipment while reducing equipment failures and maintenance costs caused by corrosion. However, it should be noted that its resistance to strong oxidizing acids, such as concentrated sulfuric acid and concentrated nitric acid, is relatively weak. Therefore, when selecting and using it, an assessment should be made based on the specific chemical environment.

(III) Self-Lubrication and Maintenance-Free

The surface of UHMWPE chain guide wear strips is extremely smooth, with excellent self-lubricating properties. Its friction coefficient is only 0.05 – 0.1, which is equivalent to that of polytetrafluoroethylene (PTFE). This characteristic enables it to greatly reduce the frictional resistance between the chain and the guide during operation, lower the energy consumption of the equipment during operation, and also effectively reduce noise, with the operating noise being reduced to below 60dB. In automated production lines, relying on its self-lubricating property, UHMWPE chain guides do not require additional lubricating oil, which reduces pollution caused by lubricating oil leakage, lowers maintenance costs and workload, and improves production efficiency. It is an ideal choice for enterprises pursuing efficient and clean production.

(IV) Lightweight and Environmental-Friendly

The density of UHMWPE chain guide wear strips is only 0.93 – 0.94g/cm³, which is lower than that of water. This makes it more convenient during installation and transportation, can effectively reduce the overall weight of the equipment, and reduce energy consumption. It is non-toxic and odorless, meets food-grade standards, and can be in direct contact with food and pharmaceuticals. In food and beverage production lines, it will not pollute the products, ensuring food safety; in pharmaceutical conveying equipment in the pharmaceutical industry, it can also ensure the purity of pharmaceuticals, meeting the strict hygiene and safety requirements of these industries. It is the best choice for green and environmentally friendly enterprises that focus on product quality.

(V) Excellent Low-Temperature Resistance

In terms of low-temperature resistance, UHMWPE chain guide wear strips also perform excellently. It can maintain stable performance within the temperature range of -200°C to 80°C, and can work normally whether in cold polar regions or low-temperature warehouses of cold chain logistics. In outdoor logistics equipment in northern winters, guides made of ordinary materials are prone to becoming brittle and cracking at low temperatures, while UHMWPE chain guides can operate stably, ensuring the smooth flow of logistics and transportation. In the process of cold chain food processing and transportation, it can adapt to low-temperature environments, ensuring the quality and safety of food and providing reliable support for the development of the cold chain industry.

Wide Application Scenarios

The outstanding performance of UHMWPE chain guide wear strips enables it to be widely used in numerous industries.

(I) Logistics Industry

In the logistics industry, especially in express sorting equipment, chain guides are crucial for ensuring efficient operation. The express industry has a huge business volume, and sorting equipment needs to operate continuously for a long time, with chain guides bearing high-intensity friction and impact. Relying on its excellent wear resistance, UHMWPE chain guide wear strips can effectively reduce the wear between the chain and the guide, ensuring the stable operation of the equipment. After a large logistics center’s sorting equipment adopted UHMWPE chain guide wear strips, the equipment’s failure downtime was significantly reduced, from an average of 5 times per month to 1 time per month, effectively ensuring the efficient progress of logistics sorting. Its impact resistance can also cope with the impact of packages on the chain during the sorting process, reducing chain damage and guide deformation caused by impact, and providing reliable support for the efficient operation of the logistics industry.

(II) Food Processing Industry

The food processing industry has extremely high requirements for hygiene and equipment stability. UHMWPE chain guide wear strips have obtained food-grade certification, meet strict food safety standards, can be in direct contact with food, and will not cause any pollution to food. In food production lines, chain guides are in frequent contact with food. UHMWPE chain guide wear strips will not produce scratches, avoiding chain jamming and ensuring the continuity of food production. Its corrosion resistance can also resist the erosion of common acids, alkalis, and other substances during food processing. In pickled food production lines, the guide is in long-term contact with an environment containing salt and acidic substances, and UHMWPE chain guide wear strips can remain stable without being corroded, ensuring the normal operation of the equipment and safeguarding the quality and safety of food.

(III) Mining Industry

The working environment of the mining industry is harsh, and chain guides face great challenges. UHMWPE chain guide wear strips demonstrate an ultra-long service life in the mining industry. In equipment such as ore conveyors, crusher material guide chutes, and sintering chain plate machines, the chain needs to carry heavy ores and operate in harsh environments such as high dust and high humidity. The high load-bearing capacity of UHMWPE chain guide wear strips enables it to easily cope with the weight of heavy ores, and its resistance to abrasive wear can effectively resist the friction of ore particles and reduce wear. After a mining enterprise used UHMWPE chain guide wear strips, the equipment maintenance cost was significantly reduced, from the original annual maintenance cost of 1 million yuan to 300,000 yuan per year. At the same time, the production efficiency was significantly improved, with the output increasing by 20%, bringing considerable economic benefits to the mining enterprise.

(IV) Other Industries

- Automated Production Lines: The self-lubricating property and high-precision guiding function of UHMWPE chain guide wear strips can ensure that the chain drives components to move accurately, improving the degree of production automation and product quality. In the automated production lines for electronic equipment manufacturing, chain guides need to ensure the accurate transportation and positioning of electronic components. UHMWPE chain guide wear strips can meet this demand and reduce the defect rate.

- Port Loading and Unloading Systems: Its impact resistance and wear resistance enable it to adapt to the frequent loading and unloading of large goods and harsh marine environments. In the chain system of container cranes, UHMWPE chain guide wear strips can withstand huge impact forces, reduce equipment failures, and improve loading and unloading efficiency.

- Pharmaceutical Industry: Its characteristic of meeting pharmaceutical hygiene standards can be applied to pharmaceutical production and conveying equipment, ensuring the purity and safety of pharmaceuticals. In pharmaceutical packaging production lines, chain guides need to ensure the hygiene and accuracy of pharmaceutical packaging. UHMWPE chain guide wear strips can meet these requirements and provide strong support for the development of the pharmaceutical industry.

Choose Our Products to Start an Efficient Industrial Journey

(I) Product Advantages

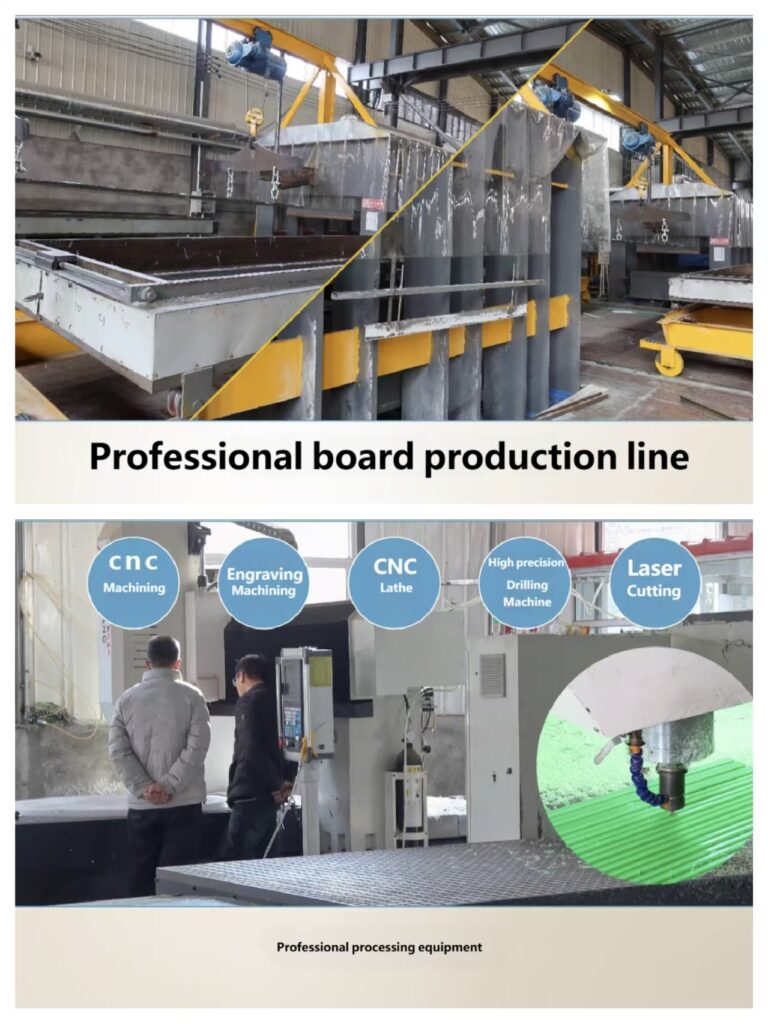

Our UHMWPE chain guide wear strips are processed using self-produced high-molecular-weight plates, which have a significant advantage in molecular weight—up to over 3 million, far exceeding similar products on the market. This makes their wear resistance and impact resistance even more excellent. Even in high-load and high-friction working environments, they can still maintain stable performance, and their service life is extended by more than 30% compared with ordinary products. We use precision machine tool processing equipment to ensure product precision and surface roughness. The contact with the chain is closer, and the guidance is more accurate, which can effectively reduce the deviation and vibration of the chain and improve the stability of equipment operation.

(II) Customization Services

We are well aware that different industries have different needs for chain guide wear strips, so we provide comprehensive customization services. We accurately match the guide size according to different chain specifications to ensure a perfect fit. In terms of shape design, whether it is a conventional linear type, a complex curved type, or a special-shaped type, our professional team can design and manufacture according to the customer’s equipment structure and operation requirements.

Call to Action

If you are troubled by the wear problem of your equipment’s chain guides or hope to improve the performance and efficiency of your equipment, then you may wish to choose our UHMWPE chain guide wear strips. We have a professional team that can provide you with comprehensive services and support and answer any questions you may have. Let us work together to start a new journey of efficient and stable industrial production for you and experience the outstanding performance and great value brought by UHMWPE chain guide wear strips.