In the operation process of a chain plate conveyor, the turning section is the “weak link” most prone to failures. Below, we will analyze how it ensures the stable and efficient operation of the chain plate during turning from three aspects: turning pain points, guide rail adaptive design, and practical effect verification.

1. Core Pain Points of Chain Plate Conveying Turning: Why Are Traditional Guide Rails Inadequate?

In the straight section of a chain plate conveyor, the chain plate only needs to run at a constant speed in a fixed direction, and the requirements for the guide rail are relatively simple. However, after entering the turning section, affected by three factors—centrifugal force, chain plate pitch error, and material center-of-gravity deviation—traditional metal guide rails or general-purpose guide rails are often unable to provide an effective solution.

1.1 Chain Plate Deviation: Trajectory Deviation Causing Material Falling

When the chain plate turns, it generates an outward centrifugal force. If the guide rail has no precise guiding structure, the edge of the chain plate is likely to break away from the constraint of the guide rail, resulting in left-right deviation (the deviation usually reaches 1-3mm). Especially when conveying boxed or barreled materials, the deviation will cause the materials to collide with the rack and even fall, resulting in material loss and equipment shutdown. Traditional general-purpose guide rails have no groove design adapted to the chain plate and only rely on plane support, which cannot effectively resist centrifugal force, so the deviation problem is particularly prominent.

1.2 Severe Local Wear: Sharp Reduction in Service Life of Guide Rails and Chain Plates

The contact between the chain plate and the guide rail during turning is not uniform in force; instead, the inner edge of the chain plate and the curved surface of the guide rail form “local extrusion friction”. Traditional metal guide rails have high surface hardness but poor toughness, and are prone to scratches and dents after long-term extrusion. At the same time, the edge of the chain plate will also be worn due to friction, leading to an increase in the chain plate pitch and further aggravating the deviation. Data shows that the wear rate of traditional metal guide rails in the turning section is 3-4 times that in the straight section, and they need to be replaced every 6-12 months on average, resulting in high maintenance costs.

1.3 High Operating Resistance: Increased Energy Consumption and Excessive Noise

When the chain plate turns, it needs to overcome both “turning friction” and “additional pressure caused by centrifugal force.” Traditional metal guide rails have a high friction coefficient (0.15-0.3), which significantly increases operating resistance: on the one hand, the motor must output greater power to drive the chain plate through the turn; on the other hand, the high friction generates harsh noise (75-85 dB), far exceeding the noise standard (≤65 dB) for food and pharmaceutical workshops, thus affecting the working environment.

1.4 Low-Temperature/Heavy-Load Scenarios: Loss of Turning Stability

In factories in cold regions or cold-chain conveying scenarios (-20℃ to -40℃), traditional metal guide rails are prone to embrittlement and may crack when squeezed by the chain plate. When conveying heavy materials (such as auto parts with a single chain plate load > 30kg), the rigid support of the metal guide rail cannot buffer the turning pressure, which is likely to cause deformation of the guide rail, jamming or even breakage of the chain plate. These problems will be amplified in the turning section, directly affecting the stability of the entire conveying system.

2. UHMWPE Chain Plate Curved Guide Rails: Three Core Designs for Turning Scenarios

The reason why UHMWPE chain plate curved guide rails can solve the above pain points lies in their three customized designs around the “turning” scenario, adapting to the chain plate turning needs from three aspects: structure, material, and process.

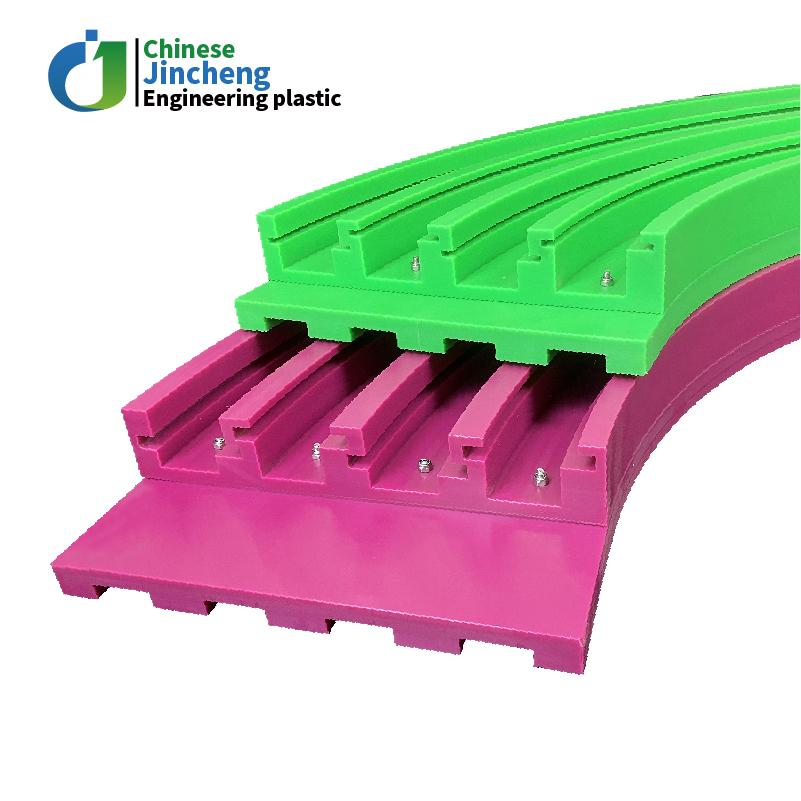

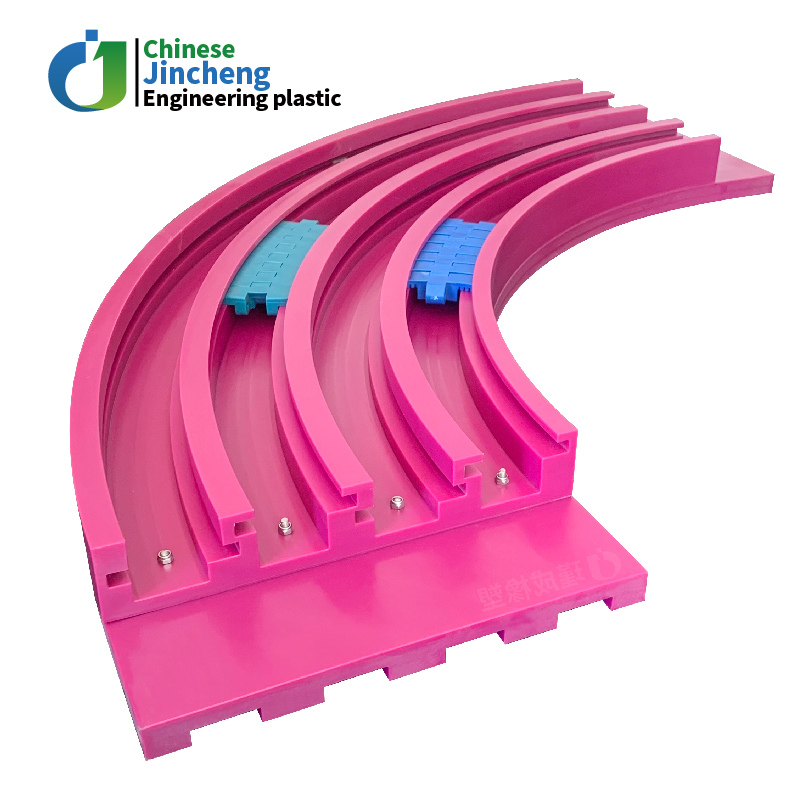

2.1 Curved Structure + Custom Groove: Accurately Resisting Centrifugal Force and Preventing Deviation

To address the centrifugal force during turning, the guide rail adopts a design where “the curved curvature accurately matches the turning radius of the conveyor”. Whether it is a 90°, 180°, or custom-angle turn, the curved radius of the guide rail is completely consistent with the turning radius of the conveyor rack, ensuring that the chain plate runs along a fixed trajectory when turning.

More importantly, the groove reserved on the inner side of the guide rail, which is designed to match the edge of the chain plate, can be “accurately engaged” with the chain plate edge — this design is like adding a “turning track” to the chain plate, effectively resisting centrifugal force. Even during high-speed turning (chain plate speed 1.2–1.5 m/s), it can maintain stable trajectory, completely solving the problem of material falling.

2.2 UHMWPE Material: Wear Resistance + Self-Lubrication to Reduce Turning Friction

To address the pain points of high wear and high resistance during turning, the guide rail is made of ultra-high molecular weight polyethylene (UHMWPE) raw material, whose two major characteristics are perfectly adapted to the turning scenario:

Superior wear resistance: The material’s wear resistance is 6-8 times that of ordinary steel, and it has excellent toughness. Local extrusion friction during turning will not cause surface scratches or dents. The service life of the guide rail can reach 5-8 years, which is 4-6 times that of traditional metal guide rails. At the same time, its smooth surface can reduce the wear of the chain plate edge, and the chain plate replacement cycle is extended by 2-3 times.

Ultra-low friction coefficient: The surface friction coefficient of the material is only 0.05-0.11, which is equivalent to the friction coefficient of an ice surface and much lower than that of metal guide rails. During turning, the frictional resistance between the chain plate and the guide rail can be reduced by 40%-60%.

2.3 Low-Temperature Toughness + Impact-Resistant Process: Adapting to Complex Turning Working Conditions

Optimization of low-temperature toughness: By adjusting the molecular weight (≥3 million) of UHMWPE and the proportion of additives, the guide rail can still maintain good toughness in the low-temperature environment of -40℃ to -60℃ without the risk of brittle fracture. In the test of a cold-chain food factory in Northeast China, the guide rail operated continuously for 2 years at -30℃ without any cracks or deformation, and the turning stability was consistent with that in the normal temperature environment.

Impact-resistant process: Self-produced “high-temperature molded” ultra-high molecular weight polyethylene (UHMWPE) plates are used and processed by precision machine tools, which form a uniform molecular structure on the curved surface of the guide rail. Even if materials accidentally collide with the guide rail, it can quickly buffer the pressure, avoid deformation, and ensure the smooth turning of the chain plate.

3. Practical Effect Verification in Turning Scenarios: Value Witnessed by Three Industry Cases

UHMWPE chain plate curved guide rails have demonstrated significant application value in turning scenarios of different industries. The following are the practical effects of three typical cases:

3.1 Case 1: Food Processing Industry – Turning Conveying of Baked Food Trays

The chain plate conveyor line of a large baking enterprise needs to complete a 180° turn (turning radius 800mm) to convey tray conveyors (with a single tray load of 5kg). Previously, when using stainless steel guide rails, the trays collided with the rack due to deviation, resulting in an average daily material loss of about 5kg. At the same time, the turning noise reached 82dB, which did not meet the workshop standards.

After replacing with UHMWPE chain plate curved guide rails:

- The groove design accurately clamps the chain plate, controlling the deviation within ±0.1mm. There is no collision or falling of trays, and the material loss is reduced to zero.

- The operating noise is reduced to 60dB, meeting the environmental protection requirements of food workshops.

- The guide rail shows no obvious wear after 3 years of use. Compared with stainless steel guide rails (replaced every 6 months), the maintenance cost is reduced by 90%.

3.2 Case 2: Automobile Manufacturing Industry – Heavy-Load Turning Conveying of Engine Components

The chain plate line of an auto parts factory needs to make a 90° turn (turning radius 1200mm) to convey engine cylinder blocks (with a single chain plate load of 40kg). Previously, when using cast iron guide rails, due to rapid wear during heavy-load turning, the guide rails needed to be replaced every 8 months. In addition, the wear of the chain plate edge led to an increase in pitch, requiring chain plate replacement every 12 months, resulting in high maintenance costs.

After replacing with UHMWPE chain plate curved guide rails:

- The wear resistance of the guide rail is improved, and it can operate normally for 5 consecutive years without deformation or depression.

- The wear rate of the chain plate edge is slowed down, and the replacement cycle is extended to 3 years.

- The operating resistance is reduced, the motor energy consumption is reduced by 22%, and the annual electricity cost is saved by about 18,000 yuan.

3.3 Case 3: Cold-Chain Logistics Industry – Turning Conveying of Frozen Meat Trays

The chain plate line of a cold-chain logistics center operates in an environment of -25℃, needing to complete a 90° turn (turning radius 600mm) to convey frozen meat trays (with a single tray load of 15kg). Previously, when using ordinary plastic guide rails, they were prone to brittle fracture at low temperatures and needed to be replaced every 3 months, and were prone to jamming during turning.

After replacing with UHMWPE chain plate curved guide rails:

- It has excellent low-temperature toughness, operating continuously for 2 years at -25℃ without brittle fracture, and turning smoothly without jamming.

- The surface of the guide rail is non-ice-sticking, eliminating the need for frequent cleaning and reducing downtime.

- The maintenance cycle is extended from 3 months to 24 months, and the maintenance cost is reduced by 87.5%.

Conclusion

In the chain plate conveying system, “turning” is only a section, but it directly determines the efficiency, service life, and cost of the entire system. Through customized design for the turning scenario, UHMWPE chain plate curved guide rails start from the four pain points of deviation, wear, energy consumption, and working condition adaptation, providing enterprises with a “low-maintenance, high-stability, low-cost” solution.

If your chain plate conveying system is troubled by problems such as turning deviation and excessive wear, please provide the turning radius of your conveyor, chain plate parameters, and working condition requirements, and our technical team will customize an exclusive guide rail solution for you.