In automated packaging production lines, the bottle dividing screw is a hidden efficiency “engine”. With its precise spiral structure design, it achieves the orderly separation, pushing and arrangement of various bottle types, and has become a key component for realizing efficient bottle dividing operations in industries such as beverages, pharmaceuticals, and daily chemicals.

1. Bottle Dividing Screw: Customized Design to Adapt to Diverse Production Scenarios

The bottle dividing screw is not a single product, but a family of highly customized solutions.

Material Dimension

Wear-resistant and corrosion-resistant polymer materials (such as UPE, nylon, POM, PTFE) or metal materials are used, which are accurately matched according to the needs of different industries (such as the hygienic level requirements of the pharmaceutical industry and the high throughput requirements of the beverage industry). For example, the bottle dividing screw of the pharmaceutical production line needs to meet the GMP cleanliness standard, while the food and beverage industry pays more attention to the wear resistance and impact resistance of the material.

Structural Dimension

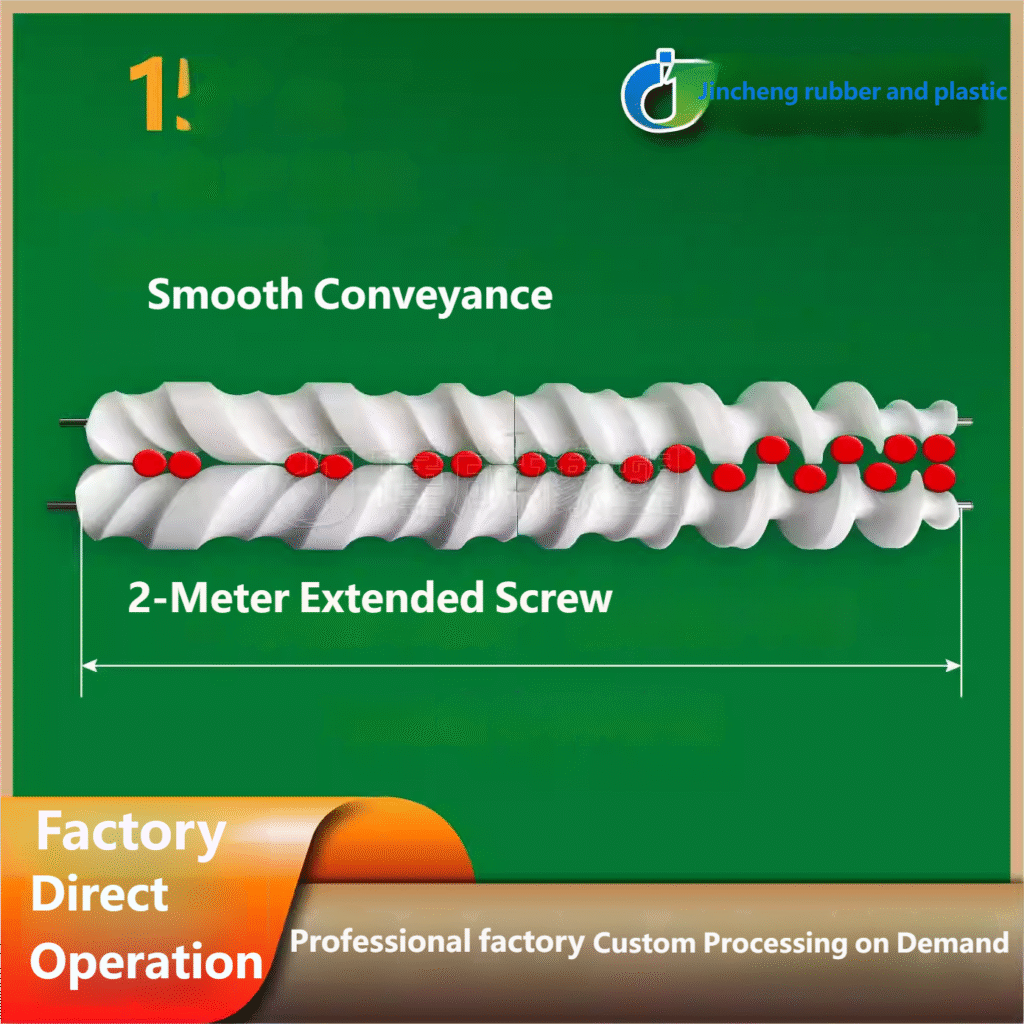

It is divided into a material pushing series screw and a bottle pushing series screw. The material pushing series screw realizes the directional pushing of materials through a continuous spiral tooth shape; the bottle pushing series screw realizes the stable bottle dividing and arrangement of different bottle types (round bottles, square bottles, special-shaped bottles) through modular spiral units (such as structures with rollers and multi-color distinction), avoiding the risk of bottle jamming and bottle falling.

2. Core Values of Bottle Dividing Screw: Precision, Efficiency, Stability and Flexible Production

2.1 Precise and Orderly, Say Goodbye to Congestion

- Intelligent Separation: Through the precise spiral track, the densely incoming bottles and cans are forced to be separated at equal distances, completely solving the problem of inlet congestion and creating perfect conditions for the subsequent filling, capping and labeling processes.

2.2 Extremely Efficient, Leap in Speed

- Speed Multiplier: Transform the chaotic “crowd flow” into an orderly “single-column march”, enabling the production line to operate stably at the maximum design speed, directly increasing the bottle dividing efficiency by several times and releasing the overall line capacity.

2.3 Stable and Reliable, Zero Loss

- Gentle Protection: The smooth spiral surface guidance avoids violent collision and friction between bottles and cans, greatly reducing the risk of bottle falling and scratching, and saving you every penny of material cost and downtime maintenance time.

2.4 Flexible Adaptation, One Screw for Multiple Uses

- Flexible and Changeable: According to the needs of different bottle types, specifications and production capacities, screws with different pitches, sizes and materials can be customized. From beverages and sauces to daily chemicals and pharmaceuticals, it can be perfectly adapted and is the cornerstone of a flexible production line.

3. How to Choose the Suitable Bottle Dividing Screw?

When selecting a model, enterprises should focus on the following points:

Production Line Requirements

Clarify the bottle size (diameter, height) and material characteristics (glass, plastic, metal) to determine the pitch, diameter and material of the screw.

Compatibility

Ensure that the bottle dividing screw is seamlessly connected with the conveying system and power unit of the existing production line, so as to avoid production line shutdown caused by structural mismatch.

Supplier Capability

Choose a supplier with customized design and production capabilities, which can provide a full-process service from demand analysis, prototype production to mass delivery, and at the same time have perfect after-sales and technical support to ensure the long-term stable operation of the production line.

Common Problems and Professional Solutions in Conveyor Screw Customization

1. Problem: Unclear about which bottle type parameters to provide, only knowing it is a “round bottle”

Consequence

Improper design of the width and depth of the spiral groove may cause bottle jamming or shaking.

Solution

Provide 3 core parameters of the bottle type, none of which can be missing:

- Maximum outer diameter of the container (such as the diameter of the PET bottle, including the label thickness);

- Container height (or the height of the section in contact with the screw, such as the height of the short can);

- Container material and weight (glass/plastic/metal, single bottle weight of 100g, etc., which affects the buffer design).

2. Problem: Only knowing the production line speed, not providing the parameters of the connecting equipment

Consequence

The connection between the screw outlet and the subsequent equipment (such as the star wheel) is stuck, and even bottle collision occurs.

Solution

Supplement 2 types of key connection parameters:

- “Pitch” of the subsequent equipment (such as the distance between adjacent slots of the star wheel);

- Equipment center distance (horizontal/vertical distance between the screw shaft and the shaft of subsequent equipment ):It determines the outlet angle and length of the screw, ensuring that bottles transition smoothly to the next process (such as filling and labeling machines).

3. Problem: Requiring “uniform pitch” and thinking that the conveying is more stable

Consequence

When the bottle enters or exits, the speed changes suddenly, resulting in impact and bottle falling.

Solution

Adopt the “three-stage variable pitch design” to adapt to the speed transition:

- Inlet section: Equal-pitch conical design to guide the bottle into smoothly;

- Middle section: Variable pitch to allow the bottle speed to be adjusted gradually;

- Outlet section: Equal pitch, matching the speed of the subsequent equipment.

4. Problem: Can different bottle types share one screw?

Consequence

The precise matching between the size of the spiral groove and the bottle type is the core of stable conveying. Sharing one screw for multiple bottle types is likely to cause bottle jamming and bottle breaking.

Solution

Customize on demand according to the bottle type. For square bottles/special-shaped bottles, a special guide structure for the spiral unit needs to be designed to prevent corner jamming.